Contributing Writer

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Categories

- Additive Manufacturing

- Aluminum Welding

- Arc Welding

- Assembly and Joining

- Automation and Robotics

- Bending and Forming

- Consumables

- Cutting and Weld Prep

- Electric Vehicles

- En Español

- Finishing

- Hydroforming

- Laser Cutting

- Laser Welding

- Machining

- Manufacturing Software

- Materials Handling

- Metals/Materials

- Oxyfuel Cutting

- Plasma Cutting

- Power Tools

- Punching and Other Holemaking

- Roll Forming

- Safety

- Sawing

- Shearing

- Shop Management

- Testing and Measuring

- Tube and Pipe Fabrication

- Tube and Pipe Production

- Waterjet Cutting

Industry Directory

Webcasts

Podcasts

FAB 40

Advertise

Subscribe

Account Login

Search

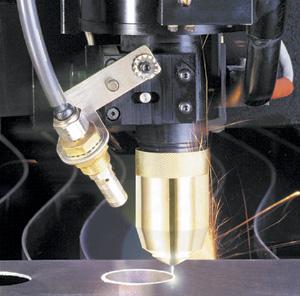

Using plasma arc cutting to clean-cut stainless steel sheet and plate

Variables to consider

- By Stephen St. Hilaire

- May 30, 2001

- Article

- Plasma Cutting

|

To cut stainless steels and other metals with plasma successfully, fabricators need the following tools:

- Precision machine motion controls

- A smooth linear drive system

- Software controls that automatically compensate and provide proper speed and acceleration and deceleration for various part features

Machine Motion Control

During the plasma cutting process, material is in the molten state inside the kerf zone. Mechanical problems such as motion irregularities cause vibrations, which transfer through the machine axis into the cut edge. These vibrations are solidified into the cut surface and can be easily mistaken for process problems. These motion irregularities and/or vibrations cause a rough-cut surface, nonlinear cut edges, and overall poor cut quality.

Torch Tip-to-Material Distance Control

To initiate the cutting process, a pneumatic probe locates the material position and provides an accurate and repeatable pierce height. After the pierce is made, the plasma arc cutting (PAC) voltage from the plasma power unit is used in a closed-loop process control system to maintain torch-to-material height while cutting.

Automatic voltage control precisely maintains the torch tip-to-material distance. This is vital when processing thin sheet and stainless steel plate.

Plasma Gases

Fabricators can process stainless steel with clean-cut surfaces by using nitrogen or a blend of oxygen and nitrogen as a plasma gas. These plasma gases provide a nonoxidizing plasma arc, which produces a clean-cut edge that is weld-ready without secondary operations.

Nitrogen also increases electrode life by preventing oxide formation on the tip of the halfnium electrode. Halfnium is used as the metallic element in the electrode, which also is compatible with oxygen as a plasma gas for steel cutting.

Pure oxygen is not recommended as a plasma gas for stainless steel cutting because of its oxidizing characteristics, which leave an oxidized, contaminated cut edge.

Compressed air is not used for cutting because it often is contaminated with water, oil, or other contaminants. These contaminants can cause regulator and solenoid valve breakdown, as well as plasma double-arcing.

Assist Gases

The type of stainless steel assist gas (or shield gas) to use varies according to the material thickness and the desired cleanliness of the cut edge. Based on each assist gas type and the material thickness, different conditions and chemical reactions result.

The five main assist gases are:

- Compressed air.

- Carbon dioxide.

- Nitrogen plus hydrogen.

- Nitrogen plus propane.

- Nitrogen.

The assist gas serves several purposes:

- It helps to prevent molten pierce metal from coming into contact with the nozzle and shield cap during piercing and cutting.

- It protects the nozzle and shield cap from double-arcing.

- It offers a method for high-speed flushing of the kerf during cutting with pure nitrogen.

- It produces a chemical reaction with hydrocarbons or other reactive gases.

| Assist Gas Type | Material Thickness (In.) | Condition |

|---|---|---|

| Clean, dry compressed air | 0.028 – 0.125 | 19 percent of the oxidizing gas flushes the kerf, leaving a gold-bronze-colored edge. |

| Carbon dioxide | 0.125 – 0.500 | A low-flow-rate carbonizing reaction provides a slag-free, brown-colored edge. |

| Nitrogen plus hydrogen | 0.500 and thicker | This combination produces a reducing atmosphere, a bluish color, and a more stable premix gas with no balancing of the two gasses. |

| Nitrogen plus liquefied petroleum | 0.187 – 0.500 | This combination produces a reducing atmosphere, breaking down propane into carbon and hydrogen. In increases cutting speed and piercing capacity, and leaves a nickel-colored edge. |

| Pure nitrogen | 0.028 – 0.078 | Inert gas flushes the kerf and evacuates it for a clean, chromelike edge with a minimum heat-affected zone. A high flow rate of assist gas also cools the process, resulting in less part distortion. |

| Figure 1. The assist gas and material thickness influence the cutting conditions and chemical reactions. | ||

Advanced Piercing Controls

Advanced piercing controls used in clean-cutting stainless steel sheet and plate include:

- Automatic pilot current control: This sets the proper pilot amperage needed for various cutting conditions and pierce heights. Pilot current relates directly to the plasma gas type, pressure, nozzle size, and piercing height.

As the material thickness increases, higher pierce heights are necessary to prevent shield cap and nozzle damage. This is achieved by using higher pilot current to connect the pilot arc to the workpiece. If pilot currents are set too high, however, premature nozzle or electrode failure can occur if the pilot arc current burns the nozzle.

- Start gas pressure control: This minimizes the amount of pilot current necessary to generate the pilot arc. The higher the plasma gas pressure setting is, the more pilot current, high frequency, and start voltage are needed to create the pilot.

- Two-step pierce height control: Piercing is initiated at 0.250 inch or less before the torch retracts to a programmed final height. After the main arc transfer has taken place, the torch automatically rises to the final height, away from pierce splatter, until the piercing is complete. The shield cap and nozzle are protected from damage even when piercing 0.750-inch stainless steel.

- Oxygen pierce metal diverter control: This system redirects and blows molten pierce metal and spatter away from the pierce area. It also protects the shield cap and nozzle. This process uses oxygen focused at the pierce point during the pierce cycle.

Polyethylene-coated Stainless Steel

Polyethylene-coated stainless steel sheet is used extensively in industries such as food service. The poly film is applied to the material after the polishing process. The film, usually 3 mils thick, is used to protect the polished stainless steel finish. Cutting this material without burning and melting the polyethylene film requires the use of nitrogen assist gas.

The nitrogen assist gas flushes the slag away from the kerf. It also shields the cutting zone from oxygen, preventing burning of the polyethylene film.

The polyethylene coating must adhere well enough to withstand the strong blowing force of the assist gas. The adhesion strength of the polyethylene coating must be at least 11 ounces pull strength per square inch, or the force of the assist gas will cause the film to lift, allowing a nitrogen air pocket to form and causing torch collision. If the gas pocket trapped beneath the poly film is more than 0.030 inch, it will catch the torch, causing cut process failure. The material should be placed on the machine cutting table with the coated side facing up. If it is not, the positive part of the circuit cannot be completed.

Considering the Variables Before Cutting

Many variables are important to consider when using the PAC process to clean-cut stainless steel sheet or plate. Fabricators must scrutinize many machine and process possibilities, no matter the sheet or plate thickness.

Stephen St. Hilaire is Senior Process Engineer for Komatsu Cutting Technologies Division, 265 Ballardvale St., Wilmington, Massachusetts 01887, phone 978-658-1650, fax 978-658-1655, e-mail steves@fineplasma.com, Web site www.fineplasma.com. Komatsu Cutting Technologies Division, a wholly owned subsidiary of Komatsu America Industries LLC, designs, manufactures, and services RASOR™ Fine Plasma systems for plate cutting.

About the Author

About the Publication

subscribe now

The Welder, formerly known as Practical Welding Today, is a showcase of the real people who make the products we use and work with every day. This magazine has served the welding community in North America well for more than 20 years.

start your free subscription- Stay connected from anywhere

Easily access valuable industry resources now with full access to the digital edition of The Fabricator.

Easily access valuable industry resources now with full access to the digital edition of The Welder.

Easily access valuable industry resources now with full access to the digital edition of The Tube and Pipe Journal.

- Podcasting

- Podcast:

- The Fabricator Podcast

- Published:

- 04/16/2024

- Running Time:

- 63:29

In this episode of The Fabricator Podcast, Caleb Chamberlain, co-founder and CEO of OSH Cut, discusses his company’s...

- Trending Articles

Sheffield Forgemasters makes global leap in welding technology

Welding student from Utah to represent the U.S. at WorldSkills 2024

Lincoln Electric announces executive appointments

Lincoln Electric acquires RedViking

Engine-driven welding machines include integrated air compressors

- Industry Events

16th Annual Safety Conference

- April 30 - May 1, 2024

- Elgin,

Pipe and Tube Conference

- May 21 - 22, 2024

- Omaha, NE

World-Class Roll Forming Workshop

- June 5 - 6, 2024

- Louisville, KY

Advanced Laser Application Workshop

- June 25 - 27, 2024

- Novi, MI