Contributing Writer

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Categories

- Additive Manufacturing

- Aluminum Welding

- Arc Welding

- Assembly and Joining

- Automation and Robotics

- Bending and Forming

- Consumables

- Cutting and Weld Prep

- Electric Vehicles

- En Español

- Finishing

- Hydroforming

- Laser Cutting

- Laser Welding

- Machining

- Manufacturing Software

- Materials Handling

- Metals/Materials

- Oxyfuel Cutting

- Plasma Cutting

- Power Tools

- Punching and Other Holemaking

- Roll Forming

- Safety

- Sawing

- Shearing

- Shop Management

- Testing and Measuring

- Tube and Pipe Fabrication

- Tube and Pipe Production

- Waterjet Cutting

Industry Directory

Webcasts

Podcasts

FAB 40

Advertise

Subscribe

Account Login

Search

Automating press brakes: Simulation software can boost productivity

- By Jerry Rush

- February 15, 2001

- Article

- Bending and Forming

|

When the right technology is available, manufacturing small lot sizes can be a shrewd business strategy.

However, producing small lots economically with press brakes has proven a major hurdle for many companies. While much progess has been made in automating turret presses and laser cutting systems, little improvement has been made for press brakes.

The main culprit is the difficulty of automating a process that converts a flat, two-dimensional (2-D) shape into a complex, three-dimensional (3-D) box. Bending is the only operation in metalworking in which such a drastic transformation occurs to the part.

This article presents three developments that are bringing automation to press brakes and, as a result, are helping fabricators meet customers' demands for smaller lot sizes. These developments are electronic storage of press brake setups and programs, bending simulation software, and higher-quality press brake automation.

Electronically Archiving Setups and Programs

Currently available software allows operators to document and upload the required setup information to a file server and then download it when the job reoccurs. When setup information is stored, it is often stored incompletely. For example, die spacing, exact tool positions, and devices to protect parts are often missing.

Far too often, program and setup information sits in unorganized piles on the floor or is stored in cabinets. Much of the time it resides only in an operator's head. Even when stored in cabinets, the information is often incomplete and difficult to find. Unless this information is fully documented and properly stored, a company has a very difficult time making small-lot manufacturing successful.

More than 50 percent of jobs on the factory floor are repeat orders. Therefore, documenting and storing the job information can mean substantial improvements in the bending department. The best people to document and store this information are press brake operators, and the best place to do it is at the machine.

Storing Job Information Electronically. One system for storing electronic job information includes the following:

- Tool number and tool graphics depicting the tool profile and dimensions

- Exact location of tools in the press brake

- Bend number, bend angle, and bend direction

- Program ram and backgauge positions with bend speed, retract positions, etc.

- Computer-aided design (CAD) files that are stored electronically and depict the geometry of press brakes on the floor

- Visual representation of lower and upper beam with toolholders, tools, and exact location of each tool

- Notes page detailing special attachments needed, such as nonscratch urethane strips and front gauging

Communication Software. Electronic archiving without instantaneous recall of the job information does not meet the need for quick access to prior setups. Therefore, a communication package linking the press brake to a file server should be included.

Scanning a bar code imprinted on the router is one alternative to retrieving all the job files needed to set up the machine. Some press brake manufacturers now build bar code scanners into their machine controllers, allowing the information to be sent directly to the brake control.

Bending Simulation Software

A second recently developed technology allows a press brake setup and program to be created and tested offline. This advancement has the potential to shift internal setup to external setup on the press brake.

In the 1970s, programs for numerically controlled (NC) turret punch presses often were created and verified at the machine. The problem with this method was that time that could have been spent punching metal was used to verify and edit programs.

During this verification, turret presses could not run revenue-producing jobs. By the end of the 1970s, turret press simulation software was created that allowed the program and tooling to be verified away from the machine. No longer did the turret press have to be tied up in nonvalue-added setup. The need for a product like this was apparent long before it was introduced, and it is now widely used.

What Took So Long?Making simulation software for a 2-D workpiece is fairly simple. However, creating simulation software that can convert a 2-D part into a 3-D part is more challenging.

Computer technology is now powerful enough to make simulation practical for automating press brakes. New press brake designs and tooling also were created to eliminate the process variation that makes automation difficult to achieve.

Bending Simulation. If a job is new, importing a CAD file is usually the first step in the bending process. Once the CAD file is imported, information on material thickness, material type, and specific brake used is entered into the electronic setup sheet. This information is later used to determine ram stroke, bend allowance, and springback.

Typically, the first step in creating the program is determining the bend sequence. Using a 3-D CAD file of the part, a programmer starts with the last bend and works backward to the first bend. In some systems, tools are selected from an electronic tool library module that contains all the necessary information.

As bend sequence is determined and appropriate tooling is selected, the bend angle, bend direction, gauge points, and bend lines are chosen. The tooling (punch, die, and die holder) is positioned along the bed of the press brake.

Once the sequence is determined, the bending data is input, and the tooling is installed, the next step is simulation.

Simulation verifies that the program, tooling, and tool setup are correct before the operator gets the job. By taking the guesswork out of the setup and program, downtime on the brake declines.

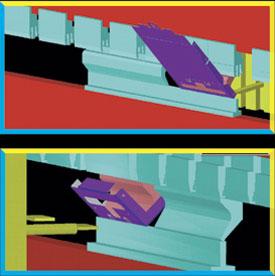

The Simulation. In the simulation process, animation is used to show the motion of the press brake and backgauge as well as the part being formed. The simulation reveals mistakes in the program, tool selections, gauge points, etc., allowing the programmer to make the needed corrections before the job reaches the press brake.

Virtual Prototyping. Virtual prototyping is a level of simulation that creates and checks designs before the part is manufactured. In this phase, corners can be inspected for fit-up before the part reaches the welding department, thereby reducing the part's time in the welding department.

Group Technology

A turret punch press is often set up to process a family of parts, a method called group technology.

Group technology is intended to yield better machine use and better material use. This method often is not possible with a conventional press brake because of the complexity of setting up for just one part. However, group technology can quickly check numerous setup combinations off-line, making it feasible for press brakes.

Simulation Software and Bending Robots. Some industry leaders are not satisfied with automating just setup and programs. They will not be content until press brakes can run by themselves 24 hours a day, seven days a week.

For these people, some simulation software has also been adapted to bending robots. The simulation includes all of the functions just discussed but, in addition, adds the robot. This means that for the first time since bending robots were introduced a decade ago, they are now practical for short-run jobs.

Conclusion

One goal of automation is to reduce, if not eliminate, dependence on a human operator.

Automating press brakes has proven to be a difficult task because of its complexity. Bending stands alone as the most difficult and labor-intensive operation on the factory floor—every press brake running on a shop floor requires an experienced, highly paid operator. When labor markets are tight, trying to staff even one shift can be a challenge, and trying to staff three shifts is nearly impossible.

Advances in bending software are bringing automation to the press brake by shifting setup from the factory floor to a programmer running a computer simulation.

About the Author

subscribe now

The Fabricator is North America's leading magazine for the metal forming and fabricating industry. The magazine delivers the news, technical articles, and case histories that enable fabricators to do their jobs more efficiently. The Fabricator has served the industry since 1970.

start your free subscription- Stay connected from anywhere

Easily access valuable industry resources now with full access to the digital edition of The Fabricator.

Easily access valuable industry resources now with full access to the digital edition of The Welder.

Easily access valuable industry resources now with full access to the digital edition of The Tube and Pipe Journal.

- Podcasting

- Podcast:

- The Fabricator Podcast

- Published:

- 04/16/2024

- Running Time:

- 63:29

In this episode of The Fabricator Podcast, Caleb Chamberlain, co-founder and CEO of OSH Cut, discusses his company’s...

- Trending Articles

Steel industry reacts to Nucor’s new weekly published HRC price

How to set a press brake backgauge manually

Capturing, recording equipment inspection data for FMEA

Are two heads better than one in fiber laser cutting?

Hypertherm Associates implements Rapyuta Robotics AMRs in warehouse

- Industry Events

16th Annual Safety Conference

- April 30 - May 1, 2024

- Elgin,

Pipe and Tube Conference

- May 21 - 22, 2024

- Omaha, NE

World-Class Roll Forming Workshop

- June 5 - 6, 2024

- Louisville, KY

Advanced Laser Application Workshop

- June 25 - 27, 2024

- Novi, MI