Contributing editor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Categories

- Additive Manufacturing

- Aluminum Welding

- Arc Welding

- Assembly and Joining

- Automation and Robotics

- Bending and Forming

- Consumables

- Cutting and Weld Prep

- Electric Vehicles

- En Español

- Finishing

- Hydroforming

- Laser Cutting

- Laser Welding

- Machining

- Manufacturing Software

- Materials Handling

- Metals/Materials

- Oxyfuel Cutting

- Plasma Cutting

- Power Tools

- Punching and Other Holemaking

- Roll Forming

- Safety

- Sawing

- Shearing

- Shop Management

- Testing and Measuring

- Tube and Pipe Fabrication

- Tube and Pipe Production

- Waterjet Cutting

Industry Directory

Webcasts

Podcasts

FAB 40

Advertise

Subscribe

Account Login

Search

Laser cell system gives job shop the home field advantage

- By Kate Bachman

- February 12, 2004

- Article

- Laser Cutting

|

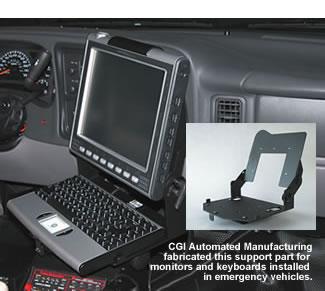

| Photo courtesy of Lund Industries Inc., Wheeling, Ill. |

No stranger to the economic fluctuations in the industry, the 50-employee company has weathered the heavy volume demands in the economic boom of the late '90s as well as the current intense global tournament that has forced U.S. metal fabricators to explore every opportunity for a home field advantage.

"We've been trying to focus on where we think we can be competitive on the shorter lead-times for companies not wanting to wait for a part to be shipped from China," said Gary Gurzynski, who manages the company with his sister, Janice Nieman.

Lead-times vary from two weeks to just a few hours. Being able to hit those kinds of fast balls requires professional-like reflexes and speedy metal forming equipment. For CGI, it meant acquiring a laser system with automated inline material handling capabilities.

Additionally, the company wanted to expand its capabilities to include light plate fabrication so it could expand into new markets, such as automotive (weldments) and retail (lighting components, fixtures, and displays).

"In deciding to get into these different arenas, we found that we weren't competitive," Gurzynski said. "We also wanted to fabricate heavier metals up to 12 inch, the type of work that we weren't able to pursue before."

Last, the company needed the flexibility to handle part runs as diverse as 25 or 1,000 and occasionally as many as 10,000.

|

"On the average, lot size has shrunk considerably," Nieman said. "A customer may want the 1,000-piece price, but will order only 100 and want them shipped 25 at a time."

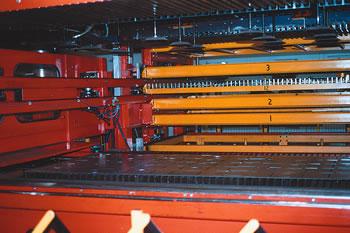

The Clincher: Automation

Gurzynski said that when evaluating laser equipment, his primary focus was on the company's material handling needs. "We looked at the time studies from a laser cutting perspective; cutting times for all the 4,000-watt machines were pretty close and they all could cut our parts at about the same rate. But a lot of labor- hours are spent on material handling every day," he said.

"For the short runs, you have to be quick, and you need to have a place to store the material and have it available, because storage space is at a premium," he continued. "With 38,000 square feet, we don't have a lot of space to store customer parts. The material handling and material storage were the biggest determining factors in selecting a system.

"For reasons of safety as well as speed, the system had to handle heavy-gauge material on both ends—getting it into the system and getting it out of the system," Gurzynski said.

"The system we were using had a load and unload capability, but it really wasn't functional on the heavier gauges," Nieman said. "You had to tab all the parts and drag them out of the machine. For the business we wanted to attract, it wasn't the right system."

|

| Photo courtesy of CGI Automated Manufacturing Inc., Cicero, Ill. |

During the high-volume period of the late 1990s, the company couldn't keep up with the demand. "We would get an inquiry for heavier-gauge material and we had to take a pass, and we had to take a pass again. After a while it became clear that we just couldn't keep passing up these opportunities. It would be certain disaster if we took on these jobs knowing our existing equipment couldn't handle it," Nieman said.

"I don't know if the decision to buy was such an analytical decision," Gurzynski said. "We knew that to stay in the game in the metal fabrication business, we needed to purchase the right equipment to be competitive."

Getting a Hit at Plate

CGI purchased a Bystronic Bystar® 3015-2 laser cell with the Bycell® automated material handling system. Bysoft® controls and software are used to direct laser cutting and material movement.

The system loads and unloads plate as well as sheet, has a 4,000-W resonator capable of cutting the plate thicknesses the company needed, and has a 14-skid material storage tower. Ten shelves store raw material, and four shelves store finished goods.

|

| Photo courtesy of CGI Automated Manufacturing Inc., Cicero, Ill. |

With the new system, the company has reduced production cycle time and now cuts plate materials on the laser. CGI has the flexibility to hit base hits as well as home runs.

"With this level of automation, our order-to-shop time has been reduced greatly," Gurzynski said. "Orders are entered the day they are received. Usually there is a contract review the next day, and they're out in the shop that same day."

"Customers might say, 'I know I'm just now faxing you the order, but can I pick it up after lunch?' It happens. And we do what we can to meet or exceed our customers' expectations," Nieman said.

The company dedicates only two operators to setting up the laser system and two turret punch press systems on each of its two shifts. Material handlers separate the parts from the skeletons, and any required finishing is done right there. Then the blanks move on to the other fabrication lines, undergo inspection, and are shipped out the door to the customer.

|

| The company focused on the material handling capabilities of the laser cutting equipment it evaluated to be able to reduce lead-times and cut plate materials. |

Installation Required a New Lineup

Installing this large unit required layout changes to the CGI facility and placement planning for all of its other fabricating equipment. "We had to have the foundation prepared. We had to install a whole new electrical service. We moved every piece of equipment in the shop and rearranged the entire production layout of the factory. Our layout plans went through many revisions before being finalized," Gurzynski said.

"We did have restrictions. Ceiling height was a big issue," Nieman said. "We have 12-ft. joists, and there were only a few places that we could place the tower and make the new system work. Then we just staged it in. We took the old laser system out and started installing the new one the next day. We actually had the new laser running within a week."

Software Hardball

The programming software allows the fabricator to accept DXF files, and CAD/CAM nesting software optimizes material usage.

"Being able to import DXF files saves a lot of time on the front end," Nieman said. "If we have to engineer those parts, it could take several hours. Importing customer DXF drawings assists us in turning our orders as quickly as we do."

Initially the operators received laser cutter operation training, then the engineers received software training. The company contracted for six training sessions to learn the application guides and how to use the system for different material types and gauges.

|

Gurzynski said the software offers additional benefits. "Some of our customers have 100 to 150 different parts needing to be cut. Each part may have requirements for one or several hundred pieces. As a result of being able to import the DXF programming files, we can separate the parts by gauge, pull in the appropriate CAD drawing and nest it, optimizing material and cutting time. Machine time is scheduled for several days. Then the order becomes one of material handling, separating, sorting, and inspecting. We never would have anticipated doing that before we got the Bycell."

CGI Automated Manufacturing Inc., 1819 S. 54th Ave., Cicero, IL 60804, 708-652-7727, fax 708-780-6028, www.cgimfg.com.

Bystronic Inc., 185 Commerce Drive, Hauppauge, NY 11788, 800-247-3332, fax 631-404-1182, saleslaser@bystronicusa.com, www.bystronic.com.

About the Author

Kate Bachman

815-381-1302

Kate Bachman is a contributing editor for The FABRICATOR editor. Bachman has more than 20 years of experience as a writer and editor in the manufacturing and other industries.

Related Companies

subscribe now

The Fabricator is North America's leading magazine for the metal forming and fabricating industry. The magazine delivers the news, technical articles, and case histories that enable fabricators to do their jobs more efficiently. The Fabricator has served the industry since 1970.

start your free subscription- Stay connected from anywhere

Easily access valuable industry resources now with full access to the digital edition of The Fabricator.

Easily access valuable industry resources now with full access to the digital edition of The Welder.

Easily access valuable industry resources now with full access to the digital edition of The Tube and Pipe Journal.

- Podcasting

- Podcast:

- The Fabricator Podcast

- Published:

- 04/16/2024

- Running Time:

- 63:29

In this episode of The Fabricator Podcast, Caleb Chamberlain, co-founder and CEO of OSH Cut, discusses his company’s...

- Trending Articles

AI, machine learning, and the future of metal fabrication

Employee ownership: The best way to ensure engagement

Steel industry reacts to Nucor’s new weekly published HRC price

Dynamic Metal blossoms with each passing year

Metal fabrication management: A guide for new supervisors

- Industry Events

16th Annual Safety Conference

- April 30 - May 1, 2024

- Elgin,

Pipe and Tube Conference

- May 21 - 22, 2024

- Omaha, NE

World-Class Roll Forming Workshop

- June 5 - 6, 2024

- Louisville, KY

Advanced Laser Application Workshop

- June 25 - 27, 2024

- Novi, MI