- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Categories

- Additive Manufacturing

- Aluminum Welding

- Arc Welding

- Assembly and Joining

- Automation and Robotics

- Bending and Forming

- Consumables

- Cutting and Weld Prep

- Electric Vehicles

- En Español

- Finishing

- Hydroforming

- Laser Cutting

- Laser Welding

- Machining

- Manufacturing Software

- Materials Handling

- Metals/Materials

- Oxyfuel Cutting

- Plasma Cutting

- Power Tools

- Punching and Other Holemaking

- Roll Forming

- Safety

- Sawing

- Shearing

- Shop Management

- Testing and Measuring

- Tube and Pipe Fabrication

- Tube and Pipe Production

- Waterjet Cutting

Industry Directory

Webcasts

Podcasts

FAB 40

Advertise

Subscribe

Account Login

Search

Safety faux pas

- By Steve Benson

- February 8, 2005

- Article

- Safety

|

| Figure 1 No Triggering Device Protection |

In the more than 25 years that I've been in the precision sheet metal trade, I have seen many examples of safety faux pas. Most were mistakes and oversights committed because of inattentiveness, lack of training, and inexperience. However, this article does not focus on these types of mistakes. Instead, it describes deliberately committed faux pas, those in which management, if not officially approving the transgressions, condones them by turning a blind eye. Most of these transgressions violate OSHA rules.

Probably the worst thing that management can do is to allow an operator to circumvent safety equipment for expedience. Safety features are built in for two reasons—the operator's safety and the employer's liability.

Disregarding the Guarding

Staging tooling in a production run is a good strategy often employed in press brake work. However, modifying the press brake to improve production while eliminating safeguards is foolish (see Figure 1).

The machine shown is Figure 1 has no operational safety equipment to keep the foot pedal from being triggered accidentally. In this example, the operator had built and installed a homemade foot bar. Why?

The operator quite simply did not want to stretch to the electric foot switch. Nor did he want to reposition his foot between the foot guard and foot pedal constantly as he moved along the press brake during setup.

As all too often happens, dumb ideas tend to become accepted practice. Seeing an increase in production and a decrease in operator complaints, this company's middle management, in all of its wisdom), authorized semipermanent foot pedals manufactured and mounted to all of its press brakes (see Figure 2).

|

| Figure 2 Mounting a Bar onto the Pedal |

Now it is not a question of if but when an accident will happen. Eventually the operator or someone just passing by the press brake will trigger the foot pedal accidentally at the wrong time. When this happens, the operator might be injured, or at the very least, the press brake program will be thrown out of sequence and a part will be wasted.

When multiple operators are working together, no more then one operator should have access to the switch or foot bar. This duty should never be shared! The operator in charge must make sure coworkers are clear of the pinch point and press brake before the bending process begins. With an unguarded foot pedal, a single operator's control cannot be ensured.

Almost as bad as eliminating the pedal guard is allowing an operator to use wire ties to tie back the toe safety switch found on many new machines. Like the pedal guard, the toe switch is there to protect the operator's safety and the company's liability.

Cheating the Light Curtain

Light curtains are another source of serious safety faux pas. Operators have a real love-hate relationship with these safeguards. Hate being the stronger emotion, operators frequently eliminate or circumvent light curtains. Again, middle management decisions that permit circumventing safety equipment or safety procedures are seriously wrong.

Light curtains are routinely turned off or blocked from working. Sure, the light curtains are a pain to work with, and yes, they do slow the production process but allowing them to be turned off can be costly.

|

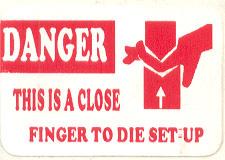

| Figure 3 Warning Decal |

Violation of the 4-inch Rule

Another common management-condoned violation involves the 4-in. rule (3 inches in Canada). Figure 3 shows a warning decal that is to be placed on the setup sheet or blueprint.

The text doesn't mention pinch points, safe operation, or OSHA guidelines—guidelines that clearly state, "You will not approach within 4 inches of the pinch point until the punch tip is at a maximum of one-quarter inch above the material."

Figure 4 shows what can happen when someone's finger is caught in the press. There is more to this picture than meets the eye. Besides a crushed finger, you might see litigation.

|

| Figure 4 Crushed Bone (finger) |

The warning decal in Figure 3 warns of possible danger but fails to include sufficient information to protect the operator and employer should litigation ensue. Again, what will be the cost incurred if an injury occurs?

The Cost ... That's Easy

A state or federal OSHA inspector might not catch the tied-back foot switch. He might not notice the new foot bar, although this is unlikely, or that the light curtain was shut off. But the day these actions result in an injury can be the day a company is destroyed.

OSHA penalties are nothing compared to what the trial lawyers can do to the comany. If you think an operator is going to cover his employer's back to save his or her job, or that insurance is going to pay up easily, guess again, my friend.

Trust me, many lawyers are waiting for injury cases resulting from these custom modifications or poorly thought out policies. For proof, just watch commercials that run on late night-TV. If the possibility of costly litigation doesn't scare you into compliance, I guess potential OSHA penalties never will.

About the Author

Steve Benson

2952 Doaks Ferry Road N.W.

Salem, OR 97301-4468

503-399-7514

Related Companies

subscribe now

The Fabricator is North America's leading magazine for the metal forming and fabricating industry. The magazine delivers the news, technical articles, and case histories that enable fabricators to do their jobs more efficiently. The Fabricator has served the industry since 1970.

start your free subscription- Stay connected from anywhere

Easily access valuable industry resources now with full access to the digital edition of The Fabricator.

Easily access valuable industry resources now with full access to the digital edition of The Welder.

Easily access valuable industry resources now with full access to the digital edition of The Tube and Pipe Journal.

- Podcasting

- Podcast:

- The Fabricator Podcast

- Published:

- 04/16/2024

- Running Time:

- 63:29

In this episode of The Fabricator Podcast, Caleb Chamberlain, co-founder and CEO of OSH Cut, discusses his company’s...

- Industry Events

16th Annual Safety Conference

- April 30 - May 1, 2024

- Elgin,

Pipe and Tube Conference

- May 21 - 22, 2024

- Omaha, NE

World-Class Roll Forming Workshop

- June 5 - 6, 2024

- Louisville, KY

Advanced Laser Application Workshop

- June 25 - 27, 2024

- Novi, MI