Contributing Writer

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Categories

- Additive Manufacturing

- Aluminum Welding

- Arc Welding

- Assembly and Joining

- Automation and Robotics

- Bending and Forming

- Consumables

- Cutting and Weld Prep

- Electric Vehicles

- En Español

- Finishing

- Hydroforming

- Laser Cutting

- Laser Welding

- Machining

- Manufacturing Software

- Materials Handling

- Metals/Materials

- Oxyfuel Cutting

- Plasma Cutting

- Power Tools

- Punching and Other Holemaking

- Roll Forming

- Safety

- Sawing

- Shearing

- Shop Management

- Testing and Measuring

- Tube and Pipe Fabrication

- Tube and Pipe Production

- Waterjet Cutting

Industry Directory

Webcasts

Podcasts

FAB 40

Advertise

Subscribe

Account Login

Search

Building a better business model

Strategic planning basics for automotive stampers to improve profit

- By Jason C. Brewer

- October 11, 2001

- Article

- Shop Management

Automotive metal stamping companies today face increasing challenges, including lower sales volumes, greater price reduction demands from customers, and rising energy and labor costs. During such challenging times manufacturers tend to focus on short-term tactical issues such as employee layoffs, shop floor cost-cutting, and redoubled sales efforts.

While these short-term actions may be appropriate, the long-term success of your company depends on the strength of the strategy captured in your enterprise business model. With a strong, clearly defined and deployed business model, automotive stamping companies may be able to generate more than twice the profits of an average competitor, even in today's challenging environment.

|

| Figure 1: An enterprise business model contains four elements that define the strategy of an organization. The strength of that strategy determines long-term success of your company. |

Elements of a Business Model

An enterprise business model contains four elements that define an organization's strategy (see Figure 1):

1. Customers. This element describes the characteristics of the customers your company wants to serve. More important, it describes the characteristics of the customers willing to pay for the value your company provides. Profitable companies carefully select their customers, not the other way around.

To document this element, begin by listing the customers you presently have. Review this list and identify your best customers. Which customers are best to work with? Which customers are most profitable for you? Next, describe the common characteristics of your best customers.

Document the descriptions in the "Customers" element of the business model. An example of an item in this element is "Tier 1 cooling system suppliers without internal stamping capabilities."

2. Scope. This element describes the scope of products and services offered to the target customers and identifies which products and services are provided internally and which are provided by a partner or supplier to your company.

To document this element of the business model, list the services your company provides. Some examples include "progressive stamping up to 600 tons," "e-coating through a third party," "tool design and purchase," "tool manufacture through a third party," "program management," and "just-in-time delivery."

3. Differentiation. This business model element describes how your company is differentiated from your competitors. Document this element by identifying what your company does well that matters to the customer and positively differentiates it from your competitors. Be specific. Be critical in evaluating your list by asking yourself, "Does my customer truly view my company as being better at this than my competitors are?"

Differentiation can be difficult to identify for contract metal stamping companies. It may be that your company is not significantly differentiated from your competitors.

4. Value Capture. The final element of the business model describes how your company retains a portion of the value provided to the customer—in other words, profit. Identify what your company does well that matters to the customer, so that the customer is willing to pay for it. Or identify what your company does well that lowers your total costs.

The strength of the business model is greatly improved when what your company does well is difficult to replicate. Business models with very few or no value-capture items suggest your customer has the upper hand in the customer-supplier relationship. This normally results in below-average profitability for the supplier.

|

| Figure 2: Intellectual capital is divided into three categories. Leveraging intellectual capital is more feasible if it is built on the existing strengths of your company. |

Sources of Differentiation and Value Capture

Stamping capacity in North America substantially exceeds demand, with capacity utilization at 65 to 70 percent. With such an abundance of underused stamping presses, it is nearly impossible for your company to differentiate or capture value primarily through capital equipment. Instead, intellectual capital (knowledge that can be leveraged) can be a more effective method for differentiating and capturing value.

Several considerations drive the selection of where to build intellectual capital. An automotive stamping supplier must consider the economics and buying sensitivity factors of its targeted customers. What do your customers really need now, and what will they need in the future? How do they make money, and for what are they willing to pay?

The strategies of your leading competitors also must be considered. Attempting to differentiate with intellectual capital already built by competitors will not differentiate your company at all.

Last, identify the core competencies of your company today. Leveraging intellectual capital is more feasible if it is built on the existing strengths of your company.

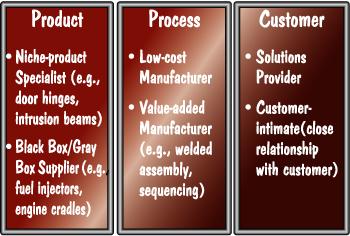

Intellectual capital can be built in three general areas (see Figure 2):

- Product

- Process

- Customer

Product Knowledge. Automotive stamping suppliers can differentiate and capture value through deep knowledge of the products they manufacture. Unique knowledge of how to manufacture a particular product most cost-effectively, especially if the product is difficult to manufacture (for instance, door hinges or intrusion beams), can differentiate you as a niche product specialist.

Knowing how to design the product for best performance or lowest manufacturing cost also can be a source of differentiation and value capture. However, this form of intellectual capital is rare among stamping companies that traditionally have little or no product design responsibility.

Process Knowledge. A common strategy pursued by automotive stamping companies is the low-cost supplier strategy. This is a way to build and leverage process knowledge. Unfortunately, many companies pursue this strategy, but only one can win.

The lowest-cost position is also difficult to maintain long-term because competitors discover new technologies or methods resulting in an even lower-cost position. Increasing the value added through assembly, welding, or sequencing processes, for example, is an alternative use of process knowledge to differentiate and capture value.

Customer Knowledge. Customer knowledge can be a powerful source for differentiation and value capture. Understanding the customer's problems even better than the customer does and using innovative problem solving can position you as a solutions provider with healthy profits. You can also develop close relationships throughout a customer's organization, which can set up your company as a preferred supplier.

Execution Counts

Simply building a strong business model will not increase profits; executing the business model produces the bottom-line results.

Once the business model is drafted, you must communicate the vision effectively and repeatedly to the organization. Then you must align resources with the business model. For example, hiring product design engineers would not be appropriate for a low-cost manufacturing strategy, while hiring manufacturing engineers focused on continuous improvement would be. Simultaneous with the realignment of resources, business processes critical to the business model also must be improved.

Accepting the Challenge

Implementing a profit-generating business model is not easy, but nearly one out of five automotive metal stamping suppliers have done it.

These suppliers have achieved success through a clearly defined and deployed business model with sustainable methods for differentiating themselves from their competitors and capturing a portion of the value they deliver. These companies have selected their customers, selected their scope of products and services, and aligned these with their methods of differentiation and value capture.

About the Author

subscribe now

The Fabricator is North America's leading magazine for the metal forming and fabricating industry. The magazine delivers the news, technical articles, and case histories that enable fabricators to do their jobs more efficiently. The Fabricator has served the industry since 1970.

start your free subscription- Stay connected from anywhere

Easily access valuable industry resources now with full access to the digital edition of The Fabricator.

Easily access valuable industry resources now with full access to the digital edition of The Welder.

Easily access valuable industry resources now with full access to the digital edition of The Tube and Pipe Journal.

- Podcasting

- Podcast:

- The Fabricator Podcast

- Published:

- 04/16/2024

- Running Time:

- 63:29

In this episode of The Fabricator Podcast, Caleb Chamberlain, co-founder and CEO of OSH Cut, discusses his company’s...

- Trending Articles

AI, machine learning, and the future of metal fabrication

Employee ownership: The best way to ensure engagement

Steel industry reacts to Nucor’s new weekly published HRC price

How to set a press brake backgauge manually

Capturing, recording equipment inspection data for FMEA

- Industry Events

16th Annual Safety Conference

- April 30 - May 1, 2024

- Elgin,

Pipe and Tube Conference

- May 21 - 22, 2024

- Omaha, NE

World-Class Roll Forming Workshop

- June 5 - 6, 2024

- Louisville, KY

Advanced Laser Application Workshop

- June 25 - 27, 2024

- Novi, MI