- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Categories

- Additive Manufacturing

- Aluminum Welding

- Arc Welding

- Assembly and Joining

- Automation and Robotics

- Bending and Forming

- Consumables

- Cutting and Weld Prep

- Electric Vehicles

- En Español

- Finishing

- Hydroforming

- Laser Cutting

- Laser Welding

- Machining

- Manufacturing Software

- Materials Handling

- Metals/Materials

- Oxyfuel Cutting

- Plasma Cutting

- Power Tools

- Punching and Other Holemaking

- Roll Forming

- Safety

- Sawing

- Shearing

- Shop Management

- Testing and Measuring

- Tube and Pipe Fabrication

- Tube and Pipe Production

- Waterjet Cutting

Industry Directory

Webcasts

Podcasts

FAB 40

Advertise

Subscribe

Account Login

Search

Lean and Mean

How a $50 million stamper became more efficient, profitable

- April 6, 2004

- Article

- Shop Management

|

The metal stamping industry is facing many challenges, such as increased raw material prices, pressure from automotive industry OEM and Tier 1 and Tier 2 customers to cut costs, and increased competition from low-cost offshore stampers.

To stay profitable, stampers have to reduce prices every year and run their businesses less expensively. This means controlling costs by reducing inventory, which includes raw material, work-in-progress (WIP), and finished goods. It also means reducing in other areas such as premium freight charges by improving delivery times; reducing overtime; improving scheduling visibility so jobs can be set up faster and completed on time; and planning ahead to optimize scheduling of purchased raw materials, packaging, and returnables.

Going Lean

Olson International Ltd., a high-volume progressive-die metal stamper serving the automotive and electronics industries, adopted an ambitious program of technology and automation to become leaner in its Lombard, Ill., and Matamoros, Mexico, stamping facilities. The stamper went beyond the basics of stream mapping, quick die change, and kaizan to do it.

"Those programs were a good start, but we wanted to take our operation to the next level by upgrading our enterprise resource planning [ERP] system by adding advanced planning and scheduling [APS] modules and automating secondary operations to reduce labor costs," said Tim Gleason, president and COO of Olson International.

Looking for Lean Solutions

The first stages of implementing lean manufacturing principles began with the formation of a cross-functional team. The team comprised members from purchasing, production, production planning, logistics, engineering, and IT.

Among the team's early successes was the reduction of inventory days from 39 to 28 in one quarter. This initial reduction resulted from implementing basic lean manufacturing principles such as just-in-time (JIT) material delivery and smaller run sizes. Inventory levels continued to drop over the next four quarters, though not at the same rate.

The team decided that a more powerful APS tool was needed to continue managing the downward trend. The search focused on finding an APS system that would integrate seamlessly with the company's existing ERP system. Emphasis also was placed on acquiring a fast, easy-to-use Web-based system.

Investing in APS

The main objectives in selecting an APS module were to find a subsystem to help management improve delivery performance, reduce or eliminate premium air freight, reduce overtime, further reduce inventory, and improve customer service.

"We were already using the SyteLine ERP system from MAPICS Inc. and found that the recently developed MAPICS APS system perfectly fit our search criteria," Gleason said. "We brought the system online in January 2003 and tracked measurable benefits through the course of the year. Delivery performance has been maintained at 98.5 percent or better; inventory has been reduced to less than 20 days; and customer service now provides a customer with an accurate projected delivery date for their product."

The results achieved after installing the APS system, in conjunction with lean manufacturing principles, set an example for other "lean teams" within the company. Each team now understands the possibilities for improvement through new technology and is carefully analyzing industry best practices.

How APS Works

APS puts customer orders at the center of the business model and reduces costs by allowing a company to synchronize manufacturing operations using orders, materials, and capacity to obtain precise delivery dates.

|

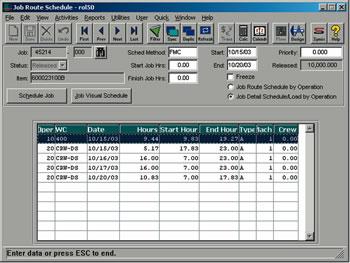

| Figure 1 This scheduling system budgets 9.44 hours for the stamping operation. This includes setup, run time, and a projected delay factor. The system then budgets 48 hours (three 16-hour days) for deburring. The job is set to start on 10-15 and should be completed on 10-20, skipping the weekend. |

"APS helped us improve by streamlining and simplifying the business process throughout the organization," Gleason said.

The APS system begins in sales. When a salesperson enters a customer's order in the ERP system, APS is launched. It searches its own database (a scaled-down version of the company's ERP system) to determine available manufacturing capacity and reserves it for incoming orders (see Figure 1).

APS accounts for every resource in the ERP routing and bill-of-material databases. All aspects of the manufacturing process are taken into account to determine lead-times. These aspects include raw material availability, material lead-time, equipment availability, labor availability, tooling availability, and any outside service process lead-time.

The salesperson is immediately notified at the time the order is entered whether the delivery date is obtainable. If the requested date is not achievable, the system provides a projected ship date and identifies the exact cause of the delay. Identifying the delay's root cause is critical so corrective action may be initiated, actions such as expediting a material supplier, using alternative equipment, or working overtime.

|

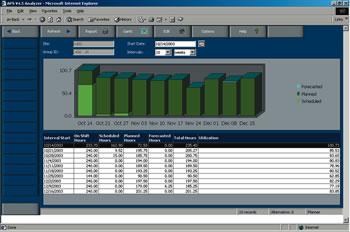

| Figure 2 A work load is projected for a certain press over the next 10 weeks. The screen provides a big picture for each workcell and is reviewed weekly by the general manager, plant manager, and scheduler to determine any long-term needs such as overtime or staffing changes. |

APS automates the entire planning and scheduling process (see Figure 2). This means that the production planner is free to be proactive in resolving conflicts or restraints. Before APS was installed, a dedicated, full-time production planner would spend three full days building a production schedule for the following week. This process is now completed in about one hour. As a result, the production planner position has essentially been eliminated.

The APS system is structured to match actual manufacturing capabilities. Unlike traditional material resource planning (MRP) systems, which assume infinite capacity, APS develops a plan based on current capabilities and work schedules. The system generates a plan for all resources required—material, press, die, labor, and packaging—and automatically resolves any constraints or bottlenecks.

APS also allows the production team to communicate material requirements to suppliers, and schedules and forecasts are automatically transmitted to suppliers based on the schedule so material arrives when it is needed. "Our raw material inventory is now less than five days, with a goal to reduce it to three days by second-quarter 2004," Gleason said.

Installing APS took less than a month, and extensive training wasn't necessary because the system uses color codes and special symbols to highlight potential delays or constraints, Gleason commented. The only installation issues involved internal problems such as inaccurate bills-of-material or inaccurate material lead-times.

Results From Installing APS

If Olson is looking out three to four days, the system recognizes all future orders and pulls orders into various departments that need to support purchasing and packaging. All this information is viewed from a desktop.

Planning labor-hour requirements for the weeks ahead was always a problem using data from previous systems. APS allows real-time decision making for today and into the future.

WIP has been reduced from six weeks to less than two weeks over the last two years.

Overtime has been reduced by one hour per employee on average for the year.

Suppliers can control and turn around the stamper's purchase orders because the system allows the user to reduce order quantities and compress times.

"Instead of overloading the supply chain with three to four weeks' [worth] of raw material, we now order quantities suppliers can best control," Gleason said. "And when customers concerned about capacity ask how we expect to handle their jobs, the APS system provides immediate detail on all future loading requirements."

When competing against low-cost offshore labor rates, Olson's operation in Matamoros, Mexico, needed to become leaner, Gleason said.

"We decided to ease the work load on employees by eliminating redundant processes or automating them," Gleason said. "Performing more secondary operations such as tapping, welding, inserting, and staking in the die is another way we've been able to cut costs."

Staying Lean

The stamper's commitment to being lean doesn't stop with the APS program. "We also are investing in management and process systems to further the installation of lean principles throughout the company," Gleason said.

Olson invested heavily in electronic data interchange (EDI) for processing customer requirements. Over 75 percent of stamping sales originate from an EDI requirement. Besides cost savings in order entry, EDI yields improved accuracy as no rekeying or reprocessing of customer order requirements is necessary. The company also can take wire drawings on EDI from customers, feed data straight into the IT system, and work on designs in their early stages, said Gleason.

"We now accept 3-D CAD files from customers and can import them directly into the coordinate measuring machine [CMM] system, which saves two or three days of CMM programming time," Gleason said. This means that programming required to measure a part is in place when the die arrives, reducing tryout time and time to market. Plus, die sensors are used extensively in both plants to protect customer tooling and ensure quality parts. Employees also are trained for multiple tasks so they can be reassigned within the plant to continue to be productive.

"We also are teaching some of our critical suppliers how to adopt lean manufacturing principles," Gleason said. "Three outside processing vendors were selected to focus on quick changeovers and reduced delivery cycles."

A program of continuous improvement is required if a stamper wants to increase its operating efficiency. A philosophy of adopting whatever effective tools may be available, such as APS, is necessary to keep the improvement initiative moving ahead.

Olson International Ltd., 50 W. North Ave., Lombard, IL 60148, 630-629-9494, fax 630-261-9707, Timg@olsonintl.com, www.metalstamper.com.

MAPICS Inc., 1000 Windward Concourse Pkwy., Suite 100, Alpharetta, GA 30005, 678-319-8000, fax 678-319-8368, www.mapics.com.

subscribe now

The Fabricator is North America's leading magazine for the metal forming and fabricating industry. The magazine delivers the news, technical articles, and case histories that enable fabricators to do their jobs more efficiently. The Fabricator has served the industry since 1970.

start your free subscription- Stay connected from anywhere

Easily access valuable industry resources now with full access to the digital edition of The Fabricator.

Easily access valuable industry resources now with full access to the digital edition of The Welder.

Easily access valuable industry resources now with full access to the digital edition of The Tube and Pipe Journal.

- Podcasting

- Podcast:

- The Fabricator Podcast

- Published:

- 04/16/2024

- Running Time:

- 63:29

In this episode of The Fabricator Podcast, Caleb Chamberlain, co-founder and CEO of OSH Cut, discusses his company’s...

- Trending Articles

AI, machine learning, and the future of metal fabrication

Employee ownership: The best way to ensure engagement

Steel industry reacts to Nucor’s new weekly published HRC price

Dynamic Metal blossoms with each passing year

Metal fabrication management: A guide for new supervisors

- Industry Events

16th Annual Safety Conference

- April 30 - May 1, 2024

- Elgin,

Pipe and Tube Conference

- May 21 - 22, 2024

- Omaha, NE

World-Class Roll Forming Workshop

- June 5 - 6, 2024

- Louisville, KY

Advanced Laser Application Workshop

- June 25 - 27, 2024

- Novi, MI