Editor-in-Chief

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Categories

- Additive Manufacturing

- Aluminum Welding

- Arc Welding

- Assembly and Joining

- Automation and Robotics

- Bending and Forming

- Consumables

- Cutting and Weld Prep

- Electric Vehicles

- En Español

- Finishing

- Hydroforming

- Laser Cutting

- Laser Welding

- Machining

- Manufacturing Software

- Materials Handling

- Metals/Materials

- Oxyfuel Cutting

- Plasma Cutting

- Power Tools

- Punching and Other Holemaking

- Roll Forming

- Safety

- Sawing

- Shearing

- Shop Management

- Testing and Measuring

- Tube and Pipe Fabrication

- Tube and Pipe Production

- Waterjet Cutting

Industry Directory

Webcasts

Podcasts

FAB 40

Advertise

Subscribe

Account Login

Search

Right on schedule

Shop management software streamlines QC Metal Fabricators' operations

- By Dan Davis

- June 12, 2006

- Article

- Shop Management

|

| The wall doesn't look like much, but it represents an important part of QC Metal Fabricators' business: the up-and-out style of hinges commonly found on many recreational vehicles. The samples represent the several hinges the company fabricates for its RV-manufacturing customers. |

QC Metal Fabricators is no longer at the mercy of a spreadsheet program as they attempt to excel at estimating and scheduling.

As any reader of The FABRICATOR® knows, estimating jobs and scheduling those jobs in a job shop environment is a tedious process. Combine that with a particularly hectic time, and that tedious job becomes that much more difficult.

QC Metal Fabricators Inc., a longtime metal fabricating fixture in Elkhart, Ind., is keeping up with the hectic schedule, despite the nature of it. A changeover to a job shop management system from Shoptech Software Corp. is helping.

The Waiting Game

QC Metal Fab is a 23-year-old fabricating operation working out of a 37,000-square-foot facility near an airport. The company, which employs 28, provides bending, punching, laser cutting, shearing, and welding services to the agricultural, automotive, medical, and RV industries. The latter makes sense considering that Elkhart is the self-proclaimed RV-manufacturing capital of the world.

"We are where people come before they want to tool a job," said Brad Stacy, QC Metal Fab's general manager. "If they want quantities that can justify the tooling, then they are going to tool it. If they can't afford the tooling, then they come to a facility like ours."

That translates into a lot of low-volume jobs, from lots of one or two to 200, Stacy added. It also creates scheduling headaches, especially when relying on Microsoft Excel® spreadsheets.

Stacy's headaches worsened when it came time to conduct a quick check of original job estimates for comparison against final job costs. Stacy had to leave his desk, hunt for the original estimate on the quote, and calculate the final figures. The disconnect between front-office accounting software and back-of-the-shop scheduling efforts was disconcerting to Stacy.

|

| The Kooima twin-head CNC plasma cutter handles the large-volume cutting jobs scheduled through the company's E2 software system. |

So in 2000 Stacy and QC Metal Fab's controller started investigating a software package that could meet their accounting, estimating, and scheduling needs. They checked out software developers and their products on the Internet and talked to their customers to see what they were using. By doing this, they weeded out some vendors.

But when it came time to make a purchase, QC Metal Fab put the brakes on a decision. The estimated wrap-up date for this project was postponed for the immediate future.

"Everyone was changing in 2000. People were getting premium dollars back then," Stacy said. "We were fortunate enough to realize that, so we bided out time, if you will, and lived with what we had."

QC Metal Fab managed to stay the course until 2003 when Stacy reinitiated the software search. By then the Y2K scare was an old punch line, and the software industry had undergone its share of consolidation. In addition, the QC Metal Fab computer infrastructure, dating back to the mid-1990s, was due for replacement.

Shopping for Shop Management

After meeting with several vendors, sitting through software demos, and whittling the final choice from three finalists, QC Metal Fab felt comfortable with the E2 shop management system from Shoptech Software Corp. Several phone calls to E2 users reinforced the selection.

Stacy said that when he asked software vendors if their software could perform a certain function, the representatives would reply, "Yes, we can get the software to do that." Shoptech, on the other hand, replied that its software already did that.

Stacy said he was very wary of having developers write special extensions for the software package QC Metal Fab would buy because he didn't want his company to be a beta site for testing out new software capabilities.

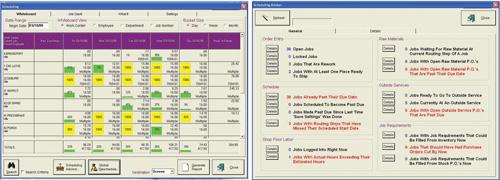

|

| E2 software provides the schedule for QC Metal Fabricators' shop floor. This sample screen shot from the scheduling screen (left) shows the viewer which jobs are open or closed and if any of them are past due. The scheduling adviser screen gives management a summary of all jobs that have yet to be shipped. |

Paul Ventura, Shoptech's senior vice president, marketing, said his company's focus on job shop environments keeps it from having to rewrite its software for every implementation.

"What it boils down to is that most of these guys are trying to accomplish the same thing: Estimate very accurately, get accurate costing so they don't take that loser job again, schedule the floor realistically, and manage their material," Ventura said. "And really trying to find out who they are making the most money off of. That's really the name of the game."

Even after waiting for three years to make a purchase, QC Metal Fab was not going to rush into this relationship. The company installed the software in early 2003 and "played around" with it for a month, according to Stacy. QC Metal Fab then ran the new software in conjunction with its legacy systems for two more months.

"So we had three months to make errors and mistakes. If we did something wrong, oh well," Stacy said.

"Then when we went live with it, we were pretty confident."

|

| For more precise metal cutting, QC Metal Fabricators relies on its 1,500-W Amada Lasmac 644II CO2 laser. |

Live From Elkhart

QC Metal Fab went live with E2 in May 2003. The last three years have proven to be very fruitful for the metal fabricating company.

"What this helped us to do is combine manufacturing and accounting," Stacy said. "And the scheduling has been a nice benefit—we are scheduling our jobs through our facility better, watching our lead-times closer, and responding quicker to when we need to work overtime."

Once a quote is approved, a job order is created. The software adds the job to a weekly schedule (a daily scheduling function is also available), creates a to-do list of operations for the shop floor, and provides a schedule of when the job is to be completed.

When the shop floor begins a job, the bar code on the job order is scanned. The system keeps track of the time, which the front office can later reference to see where the job is or to check its progress against the original quote.

"We didn't have a good means of tracking it before," Stacy said. "But since we have been using this system, I bet our on-time delivery has probably improved 10 percent when you compare where we are now to where we were.

"We are still striving for better, of course," he added.

The software also generates a complete bill of materials for each job order. Before, Stacy said, QC Metal Fab had a good idea of which materials were available from physical inventory checks, but the software has really helped to streamline billing.

No More Manual Exercises

Stacy isn't worrying about paper cuts that result from manual searches for original job estimates anymore. With the hit of a button, Stacy gets a special report that gives him an instantaneous read of actual job cost versus original estimates.

QC Metal Fab also had a special report written for incentive pay. The report provides a summary of jobs that were completed ahead of time, resulting in incentive pay, and jobs that remained open past a deadline, resulting in deductions from bonus pay.

"It's more of an incentive for the employees to work more diligently and smarter," Stacy said.

QC Metal Fab is now ready to tackle its future, keeping its 150 customers happy and generating its own products, such as a new portable motorcycle trailer (www.portachopper.com). Stacy estimates that the business is right on schedule for future success.

About the Author

Dan Davis

2135 Point Blvd.

Elgin, IL 60123

815-227-8281

Dan Davis is editor-in-chief of The Fabricator, the industry's most widely circulated metal fabricating magazine, and its sister publications, The Tube & Pipe Journal and The Welder. He has been with the publications since April 2002.

subscribe now

The Fabricator is North America's leading magazine for the metal forming and fabricating industry. The magazine delivers the news, technical articles, and case histories that enable fabricators to do their jobs more efficiently. The Fabricator has served the industry since 1970.

start your free subscription- Stay connected from anywhere

Easily access valuable industry resources now with full access to the digital edition of The Fabricator.

Easily access valuable industry resources now with full access to the digital edition of The Welder.

Easily access valuable industry resources now with full access to the digital edition of The Tube and Pipe Journal.

- Podcasting

- Podcast:

- The Fabricator Podcast

- Published:

- 04/16/2024

- Running Time:

- 63:29

In this episode of The Fabricator Podcast, Caleb Chamberlain, co-founder and CEO of OSH Cut, discusses his company’s...

- Trending Articles

How to set a press brake backgauge manually

Capturing, recording equipment inspection data for FMEA

Tips for creating sheet metal tubes with perforations

Are two heads better than one in fiber laser cutting?

Hypertherm Associates implements Rapyuta Robotics AMRs in warehouse

- Industry Events

16th Annual Safety Conference

- April 30 - May 1, 2024

- Elgin,

Pipe and Tube Conference

- May 21 - 22, 2024

- Omaha, NE

World-Class Roll Forming Workshop

- June 5 - 6, 2024

- Louisville, KY

Advanced Laser Application Workshop

- June 25 - 27, 2024

- Novi, MI