- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Categories

- Additive Manufacturing

- Aluminum Welding

- Arc Welding

- Assembly and Joining

- Automation and Robotics

- Bending and Forming

- Consumables

- Cutting and Weld Prep

- Electric Vehicles

- En Español

- Finishing

- Hydroforming

- Laser Cutting

- Laser Welding

- Machining

- Manufacturing Software

- Materials Handling

- Metals/Materials

- Oxyfuel Cutting

- Plasma Cutting

- Power Tools

- Punching and Other Holemaking

- Roll Forming

- Safety

- Sawing

- Shearing

- Shop Management

- Testing and Measuring

- Tube and Pipe Fabrication

- Tube and Pipe Production

- Waterjet Cutting

Industry Directory

Webcasts

Podcasts

FAB 40

Advertise

Subscribe

Account Login

Search

Stamper, prototyper, assembler, or fabricator

One company, many roles

- By Eric Lundin

- April 11, 2006

- Article

- Shop Management

|

| Tooling build takes as little as a week. Quasar designs the tooling, keeps an extensive variety of raw materials in its inventory, and does all the machining. |

Outsourcing. Offshoring. Layoffs. Plant closings. Newspapers and business magazines are filled with stories on the decline of U.S. industry. Nowhere is this trend more acute than in the Detroit area, with its heavy reliance on the Big Three automobile manufacturers.

It's not all gloom and doom. Quasar Industries®, a prototyping shop and low-volume manufacturer in Rochester Hills, a Detroit suburb, is growing despite the difficult manufacturing environment. The company recently added 10,000 square feet of manufacturing space.

Diversified to serve a variety of industries, Quasar provides stamping; laser cutting and welding; robotic welding; tube forming; electrical discharge machining (EDM); CNC machining; and inspection and assembly. The company designs and builds all of its own tooling, efforts that are supported by 18 CAD/CAM workstations.

The equipment is important, but the keys to Quasar's success are its employees' collective expertise and its business culture.

'We Can Build It If You Come'

Do not confuse Quasar with a typical manufacturing firm. It has no staff engineers and it has no interest in mass producing parts. Think of the company as a field of dreams for fabricators, providing them with an avenue to discover whether their idea on paper is feasible in real life.

According to Denise Higgins, company president and daughter of company founder Leroy Peterson, Quasar helps its customers save time and money by hammering out all processes involved in making a part and singling out problems that can or will occur.

|

| Quasar is approached by all manner of inventors, engineers, and hobbyists who have unusual projects. Ted Chudzik holds a headlight bezel, a replacement part for the 1970 Dodge Challenger®. A car restorer had trouble finding the part, so Quasar developed the tooling and manufactures it. "They sell like hotcakes," Chudzik said. |

If a problem arises during the prototype process stemming from the original part design, the company informs the customer immediately and shares ideas, gives suggestions, and lends advice that it thinks will help improve the process.

To ensure its customer is well-educated in every stage of the production process, Quasar allows the customer's engineering team to come in, watch as the part is formed step by step, take pictures, and ask questions. Higgins said Quasar employees have no reason to withhold information about how they have decided to form the part.

"We want to show them everything so that the next time they have a project they'll come back to us and say, 'You guys really helped us out, here's another project,'" Higgins said.

"You build these relationships, they trust you, and you advise them on what could happen," said Ted Chudzik, vice president of sales and marketing at Quasar. "The customer really appreciates that because it's saving money for them. Why waste time and money on a part that won't work?"

For a company to build and test a new part, it would have to dedicate time and money to order and install tooling and materials; put the part design through various simulations (bending, hydroforming, stamping); detect potential problems; revamp the design to demonstrate changes or improvements; and set aside space in the facility to perform all of these tasks. Many companies don't have that kind of time, money, or expertise to take on such a task.

|

| Tube benders traditionally are horizontal. To save space, Quasar had this tube bender installed so it stands on one end, which reduces the floor space required by approximately 75 percent. |

Quasar says it thrives because it can provide this service at a cost that generally is less than its clients would spend if they did the work in-house.

Speeding up the Process

Chudzik said tooling up alone can be a 30- to 35-week process for some companies, but Quasar needs as little as one week to tool up and get the part into production. It is able to make tooling in a short time because it keeps a fairly extensive supply of raw materials in its inventory and it does its own machining.

The company has found that maintaining relationships, not lowering prices, is what facilitates growth. Regardless, Higgins is aware that some companies choose a prototype shop solely on price, but warns that such a mentality can have expensive consequences.

Higgins has heard horror stories of prototype work sent to China that has left customers with an unusable part. She said that, unfortunately, some companies find out the hard way that a low price does not necessarily guarantee a job well done. She has heard of instances when a low-cost prototype company used a different type of metal than was specified for the part, making it a worthless, nonrefundable investment.

"In the end they'll come back to us and be in a greater time-frame crunch because they've already wasted time, money, and efforts into something that's defective. All companies care about is price, and then they get burned. You do get what you pay for."

|  |

| Quasar recently purchased a hydroformer that doubles as a 5,200-ton press. The hydroforming unit (right) is removable. This gives the company the versatility of two machines in the space needed for just one. The hydraulic pumps and intensifiers are out of the way, located in the basement. | |

Jack of All Trades

Automotive always has been a core industry for Quasar. Two decades ago, for instance, a big part of the company's work was for automotive seats, Chudzik said. It made the components, assembled them, and even did the electrocoating—everything except foam and upholstery.

Although automotive now is a smaller part of the company's business, it continues to do some automotive work these days. A typical application is a low-volume component it cuts to length for General Motors' HUMMER®. The standard H2® model and the HUMMER pickup truck, the H2 SUT (sport utility truck), share many components. Some H2 components have to be modified for the SUT model, so Quasar cuts some standard H2 components to a shorter length. Using standard components for both vehicles and modifying some for the lower-volume SUT model is a cost-effective strategy for the manufacturer because it doesn't have to build separate tooling to make components unique to the SUT.

Times have changed, and Quasar doesn't focus as much on automotive anymore. Diversifying into different industries such as aerospace, appliance, and defense reduces the impact when one industry hits a rough patch. This also helps keep the work environment exciting and challenging. A recent project, a deep-drawn aircraft part made from 304 stainless steel, highlights this trend.

"Every day is different. It's not the same old grind. We deal with a multitude of people and industries, which makes it interesting," Chudzik stated.

The company does more than prototype parts. It can model a specific production process—in other words, it prototypes procedures too. For example, for prototyping a part and making a small number of finished pieces, using a laser might be the fastest and easiest way to cut the necessary holes, and manual welding may be the best way to join two components. However, the client may specify using a punch or robotic welding to simulate the actual production process that it intends to use for high-volume manufacturing. By using specified processes, Quasar can provide actual cycle times to its customers, allowing them to make accurate production estimates of costs and manufacturing time.

Building Teams That Build Components

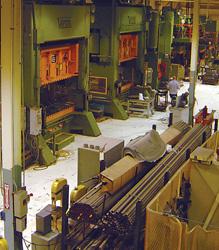

|

| Quasar's ability to make prototype parts and do low-volume production hinges on its large number of stamping presses. |

All the knowledge and experience wouldn't mean much if the company didn't recruit carefully, promote its employees' talents, and organize the staff in a productive manner.

It starts at the interview stage. Every applicant must pass a test that evaluates the candidate's mechanical aptitude. Once hired, every worker receives training on every machine and every process. This contributes to shop safety, and it has another effect: Every worker can fill every role.

"The 'That's not my job' mentality doesn't exist here," Chudzik said.

Furthermore, the company uses a team approach on every project. The teams are led by workers with more experience, allowing their knowledge and expertise to trickle down to less-experienced workers.

Solving problems isn't strictly a matter of experience and machine tools, however. A recent project involved an especially tricky part, and the project nearly came to a standstill.

"We made tool after tool and had problem after problem," Higgins said. Quasar didn't give up, though. It worked with a software vendor's finite element analysis program, PAM-STAMP™, to see if it could help Quasar develop a suitable tool. The program's evaluation of wrinkling, thinning, and tearing was a nearly perfect match for the problems Quasar had experienced with the tool, making the purchase decision a simple one.

The software makes the tooling results much more predictable. "Now if we see any thinning, weakening, wrinkling, or tearing, we can take care of it before we manufacture the tooling," Higgins said. "It's a huge savings for us and for our customers."

Past, Present, and Future

The company has changed substantially since it was founded in 1967. In 1978 it purchased its first laser cutting machine, making it one of the first prototyping shops in North America to adopt this technology, according to Chudzik. It has diversified to serve more industries. It continues to invest in new equipment and software.

How does Quasar view the future? The biggest challenge on the horizon for many manufacturers is the upcoming demographic shift as baby boomers coast into retirement and take their decades of expertise with them. Quasar is taking the challenge head-on.

While Quasar's team organization provides day-to-day information transfer from more-experienced workers to less-experienced workers, Quasar fortifies this approach with scheduled training sessions conducted by the veteran workers. Nobody can stop workers from retiring, but Quasar uses this two-pronged strategy to prevent all that expertise from leaving the premises.

And this bodes well for the company's future.

Quasar Industries, 1911 Northfield Drive, Rochester Hills, MI 48309, 248-852-0300, fax 248-852-0442, www.quasar.com

About the Author

Eric Lundin

2135 Point Blvd

Elgin, IL 60123

815-227-8262

Eric Lundin worked on The Tube & Pipe Journal from 2000 to 2022.

Related Companies

subscribe now

The Fabricator is North America's leading magazine for the metal forming and fabricating industry. The magazine delivers the news, technical articles, and case histories that enable fabricators to do their jobs more efficiently. The Fabricator has served the industry since 1970.

start your free subscription- Stay connected from anywhere

Easily access valuable industry resources now with full access to the digital edition of The Fabricator.

Easily access valuable industry resources now with full access to the digital edition of The Welder.

Easily access valuable industry resources now with full access to the digital edition of The Tube and Pipe Journal.

- Podcasting

- Podcast:

- The Fabricator Podcast

- Published:

- 04/16/2024

- Running Time:

- 63:29

In this episode of The Fabricator Podcast, Caleb Chamberlain, co-founder and CEO of OSH Cut, discusses his company’s...

- Trending Articles

AI, machine learning, and the future of metal fabrication

Employee ownership: The best way to ensure engagement

Steel industry reacts to Nucor’s new weekly published HRC price

How to set a press brake backgauge manually

Capturing, recording equipment inspection data for FMEA

- Industry Events

16th Annual Safety Conference

- April 30 - May 1, 2024

- Elgin,

Pipe and Tube Conference

- May 21 - 22, 2024

- Omaha, NE

World-Class Roll Forming Workshop

- June 5 - 6, 2024

- Louisville, KY

Advanced Laser Application Workshop

- June 25 - 27, 2024

- Novi, MI