- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Categories

- Additive Manufacturing

- Aluminum Welding

- Arc Welding

- Assembly and Joining

- Automation and Robotics

- Bending and Forming

- Consumables

- Cutting and Weld Prep

- Electric Vehicles

- En Español

- Finishing

- Hydroforming

- Laser Cutting

- Laser Welding

- Machining

- Manufacturing Software

- Materials Handling

- Metals/Materials

- Oxyfuel Cutting

- Plasma Cutting

- Power Tools

- Punching and Other Holemaking

- Roll Forming

- Safety

- Sawing

- Shearing

- Shop Management

- Testing and Measuring

- Tube and Pipe Fabrication

- Tube and Pipe Production

- Waterjet Cutting

Industry Directory

Webcasts

Podcasts

FAB 40

Advertise

Subscribe

Account Login

Search

Barnes MetalCrafters Inc

- August 9, 2010

- Article

- Shop Management

|

Tim and Nick Martin, |

Barnes MetalCrafters Inc.

252-291-0925

P.O. Box 2492

113 Walnut St. W.

Wilson, NC 27893

https://www.barnesmetal.com

sales@barnesmetal.com

By Tim Martin and Nick Martin

OPENED:

Tim Martin purchased Barnes Metalcrafters Inc. in August 1997.

WHY:

I always wanted to open my own business. I was sick and tired of the corporate world, having to work 60-80-hour workweeks, not knowing if I had a job from one day to the next. Hearing the words "You're not part of the team anymore" too many times was weighing in. I have always been in and around the manufacturing and machining business my whole life, having grown up in Flint, Mich., outside of Detroit.

I eventually ended up in New Bern, N.C., where there was way too much competition in the machining market. The opportunity arose to buy into the sheet metal industry, and I went for it. I liked the idea of taking a piece of metal, spending a little time on it, and making a finished product.

CAPABILITIES:

Our capabilities have evolved greatly! A lot of the machines and equipment that were here when I purchased the business were very old and worn. We put a lot of money and time back in the business, which allowed us to increase our output and quality. We are a custom fabricator working with mild steel, stainless, aluminum, and copper. Generally we stick to thicknesses of 1/2 in. and under. We fabricate everything from custom electrical cabinets and copper chimney caps to industrial brackets, rebar cages, and prototypes. We are set up to run small production runs on various projects, having the shop stay very flexible.

Our equipment includes:

- Cincinnati 175-ton press brake

- Prima Platino 4,000-watt laser

- Capital Robotics OTC Daihen 6-axis welding robot

- Spartan ironworker

- Kasto Functional A production saw

- 2 angle rollers-one manual, one CNC

- Several welders, hand tools, rollers, etc.

All of our capabilities mean nothing without dedicated employees. They bring their experience and knowledge to the table every day. Everyone puts their heads together and we end up doing things a lot easier and better.

|

Duke University Medical Bed |

SHOP WORKHORSE:

Our Cincinnati 175-ton press brake. It virtually runs every day. Our employees are sometimes waiting in line to use it. Everyone here knows how to program it on the touchscreen, and the Wilson segmented tooling makes it very easy to change setups. Our parts are often designed around our press brake with Autodesk Inventor. We have our drawings and tooling in sync, making the fit-up of parts very smooth.

Our Kasto saw is another go-to machine. We always need it for production runs or simple cuts for jigs and weldments.

Often overlooked, our Toyota forklift is another workhorse. It is always available to load/unload trucks and move material around in the shop. We also use it to move some of our smaller equipment around to make room for certain jobs that require a little more floor space. Also, if you throw a pallet on the forks, it becomes a worktable.

MOST UNUSUAL OR MEMORABLE PROJECT:

An embalming table would be one for sure ... but that pretty much explains itself.

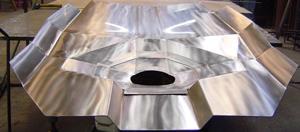

Our most memorable project would be a medical table we made for a doctoral student at Duke University (Figure 1). This was the first real job we got from our Web site. The student approached us about making a medical table for breast cancer research. It had to be made of stainless steel and developed so that a camera could rotate 360 degrees underneath the table.

We were fairly new to the 3-D CAD/modeling world with Autodesk Inventor, so this would be a challenging yet rewarding experience. The student came to us with some detailed, complicated solid models that we had to translate into the sheet metal environment. With some CAD/modeling aid from Avatech Solutions, we were able to flatten all the parts to the assembly so it could be fabricated. We went on to develop a table that looked similar to a space ship, and he was very happy with it. The table had a cameo in a story on "Good Morning America." We thought that was really cool!

GREATEST CHALLENGE:

Growing the business. I have lots of respect for the people who take a small business and grow it into a large, successful company. Taking all the pieces and putting them together is the greatest challenge.

LOOKING AHEAD:

We are looking forward to finding a niche market and developing a product. We often don't make the same production runs twice, so it would be nice to find something we could make consistently to fill in the gaps when times are slow.

ADVICE FOR WOULD-BE SHOP OWNERS:

Stay flexible! Don't be dependent on one customer, one industry, or one commodity. Also, know that you are the last one to get paid; all of your employees and creditors are first.

CONTACT:

Barnes MetalCrafters Inc.

Barnesmetal.com

Flickr Photostream

Twitter.com/BarnesMetal

Youtube.com/user/BarnesMetal

subscribe now

The Fabricator is North America's leading magazine for the metal forming and fabricating industry. The magazine delivers the news, technical articles, and case histories that enable fabricators to do their jobs more efficiently. The Fabricator has served the industry since 1970.

start your free subscription- Stay connected from anywhere

Easily access valuable industry resources now with full access to the digital edition of The Fabricator.

Easily access valuable industry resources now with full access to the digital edition of The Welder.

Easily access valuable industry resources now with full access to the digital edition of The Tube and Pipe Journal.

- Podcasting

- Podcast:

- The Fabricator Podcast

- Published:

- 04/16/2024

- Running Time:

- 63:29

In this episode of The Fabricator Podcast, Caleb Chamberlain, co-founder and CEO of OSH Cut, discusses his company’s...

- Industry Events

16th Annual Safety Conference

- April 30 - May 1, 2024

- Elgin,

Pipe and Tube Conference

- May 21 - 22, 2024

- Omaha, NE

World-Class Roll Forming Workshop

- June 5 - 6, 2024

- Louisville, KY

Advanced Laser Application Workshop

- June 25 - 27, 2024

- Novi, MI