Director of Sales

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Categories

- Additive Manufacturing

- Aluminum Welding

- Arc Welding

- Assembly and Joining

- Automation and Robotics

- Bending and Forming

- Consumables

- Cutting and Weld Prep

- Electric Vehicles

- En Español

- Finishing

- Hydroforming

- Laser Cutting

- Laser Welding

- Machining

- Manufacturing Software

- Materials Handling

- Metals/Materials

- Oxyfuel Cutting

- Plasma Cutting

- Power Tools

- Punching and Other Holemaking

- Roll Forming

- Safety

- Sawing

- Shearing

- Shop Management

- Testing and Measuring

- Tube and Pipe Fabrication

- Tube and Pipe Production

- Waterjet Cutting

Industry Directory

Webcasts

Podcasts

FAB 40

Advertise

Subscribe

Account Login

Search

Introducing cold pilger mill technology

An overview of the equipment and the process

- By Oliver Strehlau

- July 11, 2006

- Article

- Tube and Pipe Production

Cold pilgering is a longitudinal cold-rolling process that reduces the diameter and wall thickness of metal tube in one process step. Depending on the material, the cold pilger process achieves cross-section reductions of more than 90 percent in a single working cycle.

|

| Figure 1 The cold pilgering process relies on four main actions: The tube moves forward and it rotates while the ring dies move back and forth and rotate. |

Figure 1 shows the principle of the cold pilger process, and Figure 2 shows the arrangement of the machine components. The rolling tools in the cold pilger process comprise a pair of ring dies and a mandrel. The mandrel is located inside the tube in a fixed position and rotated by the mandrel thrust block. The mandrel itself is tapered in the rolling direction. The dies have matching grooves on their circumferences.

|

| Figure 2 A connecting rod drives the mill saddle back and forth. This action causes the ring dies to rotate. This action is similar to a crankshaft driving a piston in an automobile engine. Pinions mounted on each roll shaft engage two racks that are fixed to the machine housing. This arrangement uses the mill saddle's oscillating motion to generate the ring dies' oscillating rotary motion. |

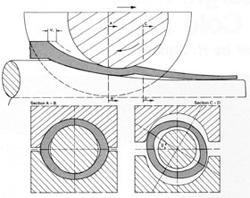

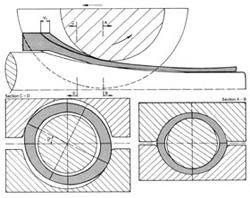

Figure 3 shows the mill saddle's rolling action. During the forward and backward strokes, the dies reduce the tube in the same way that a rolling pin rolls out pastry. The grooves' cross sections decrease along the circumference and are nearly circular.

|

|

| Figure 3 The cold pilger mill's forward motion (left) and backward motion (right) rely on the tapered cross section between the dies and the mandrel to reduce the tube's diameter and wall thickness simultaneously. |

|

In the dead-center positions of the mill saddle, the dies briefly disengage the tube. During these end-of-stroke periods, the hollow advances and rotates. Both the forward and return strokes form the tube.

Depending on the groove design, the forming process requires more than 10 steps, feeding and rotating the tube to different positions in relation to the forming die pass. The large number of small forming steps helps to ensure a constant wall thickness and nearly homogeneous material characteristics in the rolled tube.

|

|

| Figure 4 |

Optimizing the process is a matter of matching the feed increment (n) and the rotation angle (a) in the two dead-center positions with the tube material and quality requirements. In some cases, the process can achieve variations smaller than 0.5 microinch for medium ODs and wall thicknesses. The roughness value of the finished tube usually is less than that of a drawn tube. With stainless steel tubes, for example, cold pilgering can achieve Ra values smaller than 0.02 microinch.

The feed increment on the input side is an indication of the overall efficiency of the cold pilger mill operation. The length of finished tube per stroke of the mill saddle is calculated as the product

of the feed increment on the input side and the amount of elongation (the finished length minus the original length). The annual output can be estimated as the product of finished tube per stroke and the number of strokes per year, whereby the output depends on the tube material, the required dimensional tolerances, the tool design, tooling quality, and lubricant.

Materials and Applications

In most applications, the cold pilgered tubes are immediately ready for finishing or shipment. In other cases, additional cold pilgering or drawing operations are required. When additional cold-working steps are necessary, the tubes often require intermediate annealing.

The cold pilgering process is suitable for all metals. Typical materials are mild steel, stainless steel, ferritic steel, low-alloy steel, copper and copper alloys, titanium alloys, zirconium alloys, and nickel alloys (see Figure 4). Using cold pilgering to reduce precious metals is conceivable, because practically no material loss occurs. The deformation strengths of the cold pilgered tubes range from 400 N/mm2 for copper to more than 1,500 N/mm2 for special alloys.

Some applications, such as baseball bats and golf clubs, rely on cold pilgering to create the intermediate, tapered shape. Other applications are lightning poles, finned tubes, and nonround tubes with internal or external longitudinal ribs.

Characteristics of the Cold Pilger Process

This special forming process is indispensable for numerous applications, and cost-effective for many others, for a variety of reasons.

The cross-section reductions attained are higher than those achieved by other processes. Because the cold pilgering process applies pressure from all sides, it can achieve reductions up to 90 percent for copper; 80 percent for stainless steel, nickel alloys, and zircaloy; and 75 percent for high-strength titanium alloys.

The large cross-section reductions help to limit process-related conversion costs, because cold pilgering eliminates additional processes such as cleaning, annealing, pickling, cutting, handling, and straightening between drawing operations.

The homogenizing material flow in a circumferential direction facilitates substantial reductions in eccentricity. Experience has shown that the higher the eccentricity of the starting tube, the greater is the improvement in eccentricity by cold pilgering.

The many forming steps improve roundness, stress homogeneity, and surface roughness. Surface defect depths decrease in proportion to the amount of the wall thickness reduction.

During cold pilgering, practically no material loss occurs. Only the end faces of the finished tubes are out of shape and have to be cut off. The advantage of eccentricity improvements during cold pilgering is better material utilization. Reduced wall thickness deviations allow more footage of finished product to be produced from each ton of raw material.

Oliver Strehlau is the manager of sales for SMS Meer GmbH, Ohlerkirchweg 66, Mönchengladbach, Germany 41069, 49-2161-3500, fax 49-2161-350-667, info@sms-meer.com, www.sms-meer.com.

The editors of TPJ-The Tube & Pipe Journal® thank the Tube & Pipe Association, International®'s Extrusion, Drawing, and Tube Reducing Technology Council for soliciting this article.

About the Author

Oliver Strehlau

Ohlerkirchweg 66

Mönchengladbach, 41069

49-2161-3500

About the Publication

subscribe now

The Tube and Pipe Journal became the first magazine dedicated to serving the metal tube and pipe industry in 1990. Today, it remains the only North American publication devoted to this industry, and it has become the most trusted source of information for tube and pipe professionals.

start your free subscription- Stay connected from anywhere

Easily access valuable industry resources now with full access to the digital edition of The Fabricator.

Easily access valuable industry resources now with full access to the digital edition of The Welder.

Easily access valuable industry resources now with full access to the digital edition of The Tube and Pipe Journal.

- Podcasting

- Podcast:

- The Fabricator Podcast

- Published:

- 04/16/2024

- Running Time:

- 63:29

In this episode of The Fabricator Podcast, Caleb Chamberlain, co-founder and CEO of OSH Cut, discusses his company’s...

- Trending Articles

Team Industries names director of advanced technology and manufacturing

Orbital tube welding webinar to be held April 23

Chain hoist offers 60-ft. remote control range

Push-feeding saw station cuts nonferrous metals

Corrosion-inhibiting coating can be peeled off after use

- Industry Events

16th Annual Safety Conference

- April 30 - May 1, 2024

- Elgin,

Pipe and Tube Conference

- May 21 - 22, 2024

- Omaha, NE

World-Class Roll Forming Workshop

- June 5 - 6, 2024

- Louisville, KY

Advanced Laser Application Workshop

- June 25 - 27, 2024

- Novi, MI