Contributing Writer

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Categories

- Additive Manufacturing

- Aluminum Welding

- Arc Welding

- Assembly and Joining

- Automation and Robotics

- Bending and Forming

- Consumables

- Cutting and Weld Prep

- Electric Vehicles

- En Español

- Finishing

- Hydroforming

- Laser Cutting

- Laser Welding

- Machining

- Manufacturing Software

- Materials Handling

- Metals/Materials

- Oxyfuel Cutting

- Plasma Cutting

- Power Tools

- Punching and Other Holemaking

- Roll Forming

- Safety

- Sawing

- Shearing

- Shop Management

- Testing and Measuring

- Tube and Pipe Fabrication

- Tube and Pipe Production

- Waterjet Cutting

Industry Directory

Webcasts

Podcasts

FAB 40

Advertise

Subscribe

Account Login

Search

Die basics 101: Common stamping die components (Part 1 of 2)

- By Art Hedrick

- October 11, 2005

- Article

- Bending and Forming

Die Plates, Shoes, and Die Sets

|

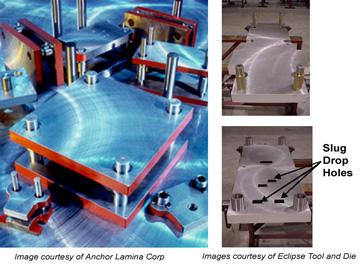

| Figure 1 Various die set types |

Die plates, shoes, and die sets are steel or aluminum plates that correspond to the size of the die. They serve as the foundation for mounting the working die components. These parts must be machined so that they are parallel and flat within a critical tolerance. The machining methods are milling and grinding. Although grinding is the most popular, a milled surface now can be obtained that is as accurate as a ground surface.

Most die shoes are made from steel. Aluminum also is a popular die shoe material. Aluminum is one-third the weight of steel, it can be machined very quickly, and special alloys can be added to it to give it greater compressive strength than low-carbon steel. Aluminum also is a great metal for shock adsorption, which makes it a good choice for blanking dies.

The upper and lower die shoes assembled together with guide pins create the die set. The lower die shoe often has machined or flame-cut holes that allow slugs and scrap created in the die to fall freely through the die shoe onto the press bed. The holes also may serve as clearances for gas springs and other die components.

The die shoe thickness is based on how much force can be expected during cutting and forming. For example, a coining die, one that compresses metal by squeezing it between an upper and lower die section, requires a much thicker die shoe than a simple bending die (see Figure 1).

Guide Pins and Bushings

Guide pins, sometimes referred to as guide posts or pillars, function together with guide bushings to align both the upper and lower die shoes precisely. They are precision-ground components, often manufactured within 0.0001 in. Although numerous specialty mounting methods can be used to install these components, there are only two basic types of guide pins and bushings—friction pins and ball bearing-style pins.

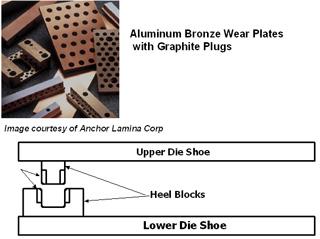

Friction pins are precision-ground pins that are slightly smaller than the guide bushing's inside diameter. Pins are made from hardened tool steel, while bushings often are made from or lined with a special wear-resistant material called aluminum-bronze. The aluminum-bronze may contain graphite plugs that help to reduce friction and wear that occur to the pins and bushings.

Friction pins also help to heel the die shoes and prevent them from moving from side to side.

|

| Figure 2 Various guide pins and bushings |

Precision or ball bearing-style guide pins comprise precision-hardened pins, ball cages, ball bearings, and bushings. Unlike friction pins, these pins ride on a series of ball bearings contained in a special aluminum ball cage that permits the bearings to rotate without falling out. These pins have several advantages. First, friction is reduced so the die can run at faster speeds without generating excessive friction and heat. Second, they allow the diemaker to separate the upper and lower die shoes easily. Third, because they use ball bearings, they can be manufactured with greater accuracy than friction pins (see Figure 2).

Remember, guide pins are meant to align the upper and lower die shoes, not to align a poorly maintained or sloppy ram in a press! Some companies try to compensate for a poorly maintained press by adding oversized guide pins or grinding the guide pin ends to a cone shape. Care must be taken when flipping die shoes over so that the guide pins are not bent.

Heel Blocks and Heel Plates

|

| Figure 3 Heel blocks |

Heel blocks are special steel blocks that are precision-machined, screwed, doweled, and often welded to both the upper and lower die shoes. They contain components called wear plates and function to adsorb any side thrust that may be generated during the cutting and forming process. They are especially important if the generated force is one-directional. Too much force generated from one direction only can cause the guide pins to deflect, which results in misalignment of critical cutting and forming components.

Most heel blocks have steel heel plates, and the heel block on the opposite shoe has a wear plate made from aluminum bronze or some other dissimilar metal. The plate selection process is critical. Using two opposing plates made of the same metal type can result in high friction, heat, and eventually galling or cold welding of the wear plates.

Heel blocks can be used to heel the die in any or all directions. Box heels often are used to heel the die in all directions (see Figure 3).

Screws, Dowels, and Keys

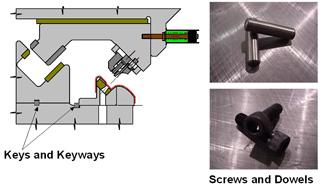

Screws fasten and secure the working components to both the upper- and lower-die shoes. The socket head cap screw is the most popular fastener used in stamping dies. This hardened tool steel screw, often referred to as an Allen head screw, offers superior holding power and strength.

|

| Figure 4 Keys, dowels and screws |

Dowels are hardened, precision-ground pins that precisely locate the die section or component in its proper location on the die shoe. Although dowels have much heeling ability, their main function is to locate the die section properly.

Keys are small, rectangular blocks of precision-ground steel that are inserted into a milled pocket in the die shoes and sections called keyways. Keys locate and heel die sections and components (see Figure 4).

While these are the most common, other components can be used in manufacturing stamping dies. These will be discussed in Part V of this series.

Editor's Note:

Part I provides an introduction to stamping.

Part II covers various forming operations.

Part III discusses several production methods used to make stamped parts.

Part IV and Part V cover common stamping die components.

Part VI explains specialty die components.

Part VII provides an overview of metals used in stamping, and Part VIII continues this discussion.

Part IX covers the mechanical properties as well as behavioral characteristics of metals.

Part X begins an in-depth look at the metal cutting process.

Part XI defines slug pulling and common causes.

Part XII describes methods for resolving slug-pulling problems.

Part XIII discusses various specialty metal cutting methods used in stamping operations.

Part XIV explains fineblanking and GRIPflow®.

Part XV describes several bending methods—wipe, coin relief, pivot, and V bending.

Part XVI continues the discussion of bending in stamping operations, focusing on rotary and reverse U bending. It also addresses the advantages and disadvantages of rotary bending.

Part XVII discusses the fundamentals of drawing and stretching.

About the Author

Art Hedrick

10855 Simpson Drive West Private

Greenville, MI 48838

616-894-6855

Related Companies

subscribe now

The Fabricator is North America's leading magazine for the metal forming and fabricating industry. The magazine delivers the news, technical articles, and case histories that enable fabricators to do their jobs more efficiently. The Fabricator has served the industry since 1970.

start your free subscription- Stay connected from anywhere

Easily access valuable industry resources now with full access to the digital edition of The Fabricator.

Easily access valuable industry resources now with full access to the digital edition of The Welder.

Easily access valuable industry resources now with full access to the digital edition of The Tube and Pipe Journal.

- Podcasting

- Podcast:

- The Fabricator Podcast

- Published:

- 04/16/2024

- Running Time:

- 63:29

In this episode of The Fabricator Podcast, Caleb Chamberlain, co-founder and CEO of OSH Cut, discusses his company’s...

- Trending Articles

AI, machine learning, and the future of metal fabrication

Employee ownership: The best way to ensure engagement

Steel industry reacts to Nucor’s new weekly published HRC price

Dynamic Metal blossoms with each passing year

Metal fabrication management: A guide for new supervisors

- Industry Events

16th Annual Safety Conference

- April 30 - May 1, 2024

- Elgin,

Pipe and Tube Conference

- May 21 - 22, 2024

- Omaha, NE

World-Class Roll Forming Workshop

- June 5 - 6, 2024

- Louisville, KY

Advanced Laser Application Workshop

- June 25 - 27, 2024

- Novi, MI