Contributing Writer

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Categories

- Additive Manufacturing

- Aluminum Welding

- Arc Welding

- Assembly and Joining

- Automation and Robotics

- Bending and Forming

- Consumables

- Cutting and Weld Prep

- Electric Vehicles

- En Español

- Finishing

- Hydroforming

- Laser Cutting

- Laser Welding

- Machining

- Manufacturing Software

- Materials Handling

- Metals/Materials

- Oxyfuel Cutting

- Plasma Cutting

- Power Tools

- Punching and Other Holemaking

- Roll Forming

- Safety

- Sawing

- Shearing

- Shop Management

- Testing and Measuring

- Tube and Pipe Fabrication

- Tube and Pipe Production

- Waterjet Cutting

Industry Directory

Webcasts

Podcasts

FAB 40

Advertise

Subscribe

Account Login

Search

99% GTAW, 100% RAD

Aesthetic welds drive classic cars

- By Stephanie Vaughan

- March 8, 2005

- Article

- Arc Welding

|

| Troy Trepanier stands next to the FastForward Fastback 1967 Mustang®, a project car restored with modifications borrowed from Ford's 2005 concept Mustang. It was made in 18 weeks with parts and accessories found and bought on eBay Motors. |

Troy Trepanier says his company does all the same things any fabrication shop does.

Sure—except that the classic cars he fabricates sell for at least $150,000.

"A lot of the stuff we do here is what a fabricator would do—we're just creating stuff a little different," said Trepanier, president of hot rod construction shop Rad Rides by Troy, Manteno, Ill.

Different, indeed. Rad Rides by Troy has stripped down, remodeled, and revitalized the likes of a 1932 Ford roadster, 1937 Ford convertible, 1972 Chevy pickup truck, 1967 Lincoln, and 1957 Chevy Nomad. This means completely gutting a vehicle and making it into a modern masterpiece.

But for Trepanier, resurrecting some of the greatest automobiles ever to hit the road means more than souping up an engine or splashing a new coat of paint on the body.

It also means perfection in every aspect of the vehicle's fabrication, including each and every weld—whether it's seen or behind the scenes.

Remarkable Restoration, Rad Results

Cars come into Rad Rides by Troy from a variety of sources, including eBay. Most cars are 1950s and 1960s model years.

The key to a high-quality restoration lies not in extremes, but in the subtleties of the work that has been done.

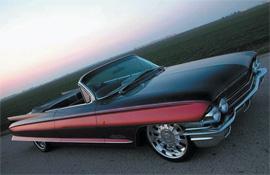

|

| Cad Attack, a 1962 Cadillac® convertible |

"We don't try to change a car to where you can't recognize it, but we try to modernize cars without losing their old look," Trepanier said. "We want you to walk up to it and say, 'I don't know what you did to it, but it looks good.'"

Customers are mostly 40-something men who want something that no one else has. Eighty percent of the company's clientele is from outside Illinois; during Practical Welding Today's visit, projects in process were for customers in California, Wisconsin, Hawaii, Pennsylvania, Texas, and Florida. Two of the more notable customers Trepanier has had are Manny Ramirez, outfielder for the Boston

Red Sox, and Joe Rogan, host of NBC's reality television series "Fear Factor."

Because his customers can't always just drop in to see how their car is coming along, Trepanier takes digital photos of the work-in-progress and e-mails them to his clients to keep them posted.

While the lowest price tag for a Rad Rides creation is $150,000, higher-end automobiles can cost up to $400,000.

But no matter the price tag, the same steps usually are taken to arrive at the finished product.

First, the metal is stripped off the exterior. The crew works on the chassis next, followed by the exhaust system, which is all built by Rad Rides' fabricators. The floor comes after that.

Fifteen tanks of argon and 25 pounds of welding rod are used during the 200 hours of welding required to complete a car. Trepanier employs seven welders (13 employees total) who run four welding machines all day long.

Currently the shop can handle seven cars at a time. Approximately three cars are completed per year, and according to Trepanier, he has enough work for the next three years.

Where the Mettle Meets the Metal

Troy Trepanier got his start in welding as a tyke, brazing together pop cans at his grandfather's shop.

Although some may have thought he was just a youngster tinkering around, Trepanier gleaned a lot of information from his first welding experiences.

|

| This exhaust system is part of Rad Rides' '70 Cuda, built for Joe Rogan, host of NBC's reality television series "Fear Factor." |

Today he practices what he learned from his grandfather. A pipefitter, Trepanier's grandfather was a perfectionist, and Troy inherited this trait and teaches it to the welders he hires.

"It's fun teaching these young guys," said Trepanier, who gets hundreds of resumes from welders who want to work for him. "The first thing I ask is, 'Can you TIG weld?' If they have a little bit of skill, I teach them how to use the machines."

Overall, hands-on welding skills are important to Trepanier, one of which is knowing how to work with several metals, such as aluminum for the fuel tanks, stainless steel, and chrome-molybdenum.

"It's all welding until it goes down to the body shop," Trepanier said. Even after it comes back from the body shop, still more welding is needed for parts such as brackets.

"The key part of it, whether or not it's exterior bodywork, is that you have to have a controlled [heat] source, so you have to use TIG. You have to know what you can and can't get away with," said Dan Holohan, who has been a welder at Rad Rides by Troy for more than three years. "You have to know how and when to control the weld," Holohan said.

Trepanier emphasizes good fabrication for quality. He also wants to make sure that anyone coming in his shop to check on a car sees beauty throughout the restoration process, not just in the end result.

"We want to show the fabrication part of it," Trepanier said. "You need to look good while you're doing it."

As a welder, Holohan agrees. Although many of his welds may be hidden within an automobile, when he sees it driving down the road, he knows he did his best to make the best welds wherever needed.

"We always strive for the perfect weld, whether it's ground or not," Holohan said. n

Rad Rides by Troy, 24 E. 3rd St., Manteno, IL 60950, 815-468-2590, www.radrides.com.

About the Author

About the Publication

subscribe now

The Welder, formerly known as Practical Welding Today, is a showcase of the real people who make the products we use and work with every day. This magazine has served the welding community in North America well for more than 20 years.

start your free subscription- Stay connected from anywhere

Easily access valuable industry resources now with full access to the digital edition of The Fabricator.

Easily access valuable industry resources now with full access to the digital edition of The Welder.

Easily access valuable industry resources now with full access to the digital edition of The Tube and Pipe Journal.

- Podcasting

- Podcast:

- The Fabricator Podcast

- Published:

- 04/16/2024

- Running Time:

- 63:29

In this episode of The Fabricator Podcast, Caleb Chamberlain, co-founder and CEO of OSH Cut, discusses his company’s...

- Industry Events

16th Annual Safety Conference

- April 30 - May 1, 2024

- Elgin,

Pipe and Tube Conference

- May 21 - 22, 2024

- Omaha, NE

World-Class Roll Forming Workshop

- June 5 - 6, 2024

- Louisville, KY

Advanced Laser Application Workshop

- June 25 - 27, 2024

- Novi, MI