- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Categories

- Additive Manufacturing

- Aluminum Welding

- Arc Welding

- Assembly and Joining

- Automation and Robotics

- Bending and Forming

- Consumables

- Cutting and Weld Prep

- Electric Vehicles

- En Español

- Finishing

- Hydroforming

- Laser Cutting

- Laser Welding

- Machining

- Manufacturing Software

- Materials Handling

- Metals/Materials

- Oxyfuel Cutting

- Plasma Cutting

- Power Tools

- Punching and Other Holemaking

- Roll Forming

- Safety

- Sawing

- Shearing

- Shop Management

- Testing and Measuring

- Tube and Pipe Fabrication

- Tube and Pipe Production

- Waterjet Cutting

Industry Directory

Webcasts

Podcasts

FAB 40

Advertise

Subscribe

Account Login

Search

Planning to cut corners on safety?

Press brake risks include pinch points, rotating rollers, and power by the ton

- By Steve Benson

- February 19, 2001

- Article

- Bending and Forming

Plainly put, press brake safety is a common sense issue. Most accidents are caused by operator inattentiveness or lack of training.

Two major categories of press brake safety are machine setup and operational safety. Along with proper tooling selection, applied tonnages, and installation, you should be aware of the real dangers inherent in press brakes.

Setup Safety

Tooling Installation. Before any tooling can be installed, the ram must be locked in the shut height position, with the ram in its most extended position. Once the press is locked into that position, the tooling can be slid safely into the press. It may take you several tries to achieve the proper gap, but it is worth the effort. The gap between the ram and the bed should be just big enough to allow easy installation without the tooling falling out.

|

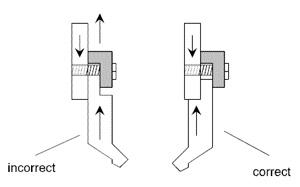

| Figure 1: The difference between the proper and improper power flow through a standard precision-ground tooling set is obvious. If power flows past the ram to the mounting bolts, you could have big problems. |

Not all tooling can be loaded universally into the press brake—many tools can be loaded correctly only one way. The best way to know if you have installed tooling correctly is to look at the tooling from the end and check where the flow of power is (see Figure 1).

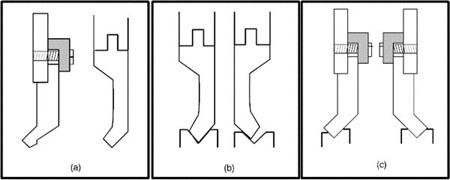

Pressure Flow. When mounting the punch into the press brake, give special attention to how the power will flow through the tool. There are two types of press brake tooling—European and standard American (see Figure 2).

Standard American tooling is completely reversible in regard to power flow, but it loses its center in the die. It also tends to waver from the backgauge to the bend line. European-style tooling is completely reversible in relation to centers, but it can be installed incorrectly.

Before installing any tooling, check for previous damage that may cause you trouble and clean the machine and the tools. Check to make sure the tooling angles match correctly for the type of forming that you are attempting. Take special care to ensure the total applied tonnage does not exceed the abilities of the tooling.

|

| Figure 2: European and standard American press brake tooling (a) are configured differently. American tooling is reversible from a power flow point of view but can lose its center on the die (b). European tooling performs in the opposite way—it’s reversible on centers (c), but susceptible to mishaps in power flow because of improper setup (see Figure 1). |

Operational Safety

Many safety-related questions need to be answered when operating press brakes. Will the stops flip out of the way in time? Will the ram open far enough to get the formed piece out of the press? Is the backgauge going to crash into the tooling?

Dry-running the forming program and the press before using any material can answer these questions. No matter how good an operator is, a dry run is one thing that should be done religiously before starting any job.

When two or more people are working together on the same press brake, only one should be designated as the operator. This duty should never be shared. The operator in charge of the brake should make certain that co-workers are clear of the press before beginning the bending process.

You never should apply any pressure on the backgauge—just a light touch is necessary to produce a good part. Pushing against the backgauge with force puts the operator in the position of leaning into the machine. One slip, and you're on your way into the dies. Pushing forcefully also is an inconsistent method because an operator cannot apply pressure equally time and time again.

|

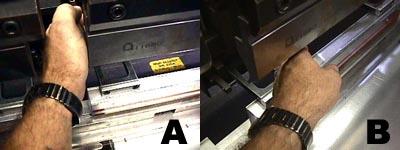

| Figure 3: Open height on a press brake should be set in a way that ensures the safety of operators' fingers. |

Setting the open height of the brake correctly is critical (see Figure 3). If you can place your finger between the punch and die, they are too far apart and you could lose a finger. If the open height is set the correct way, there is no chance of losing a finger. There are, of course, situations that require the open height to be greater than normal practice allows. In this case, the mute point should be set to allow only the material to slide between the punch and die.

Always use caution when reaching behind tooling. Make sure the backgauge is in position. If the backgauge moves while your hand is there, you can catch your fingers in the tooling.

When operating a flywheel-driven (mechanical) press brake, pay very close attention to drift. If the ram is not brought back up to or past top dead center, chances are good that the ram will drift back down the wrong way before the clutch re-engages. Not knowing where the ram is in relationship to the stroke is the single most common reason for loss of fingers and limbs among press brake operators.

Remember, with a flywheel-driven press brake, there is no way to reverse the stroke. If you are caught, the stroke has to be completed, regardless of fingers or hands in the way.

|

| Figure 4: Reaching between a punch and die set is one of the most foolish things a press brake operator can do. |

Always reach around or walk behind the press brake (see Figure 4). Never reach between the punch and die sets for any reason. If you happen to get your hand caught in the brake, it can splinter a finger bone all the way down to the marrow.

Tips for Safety

The following are some tips for avoiding serious injury at a press brake:

- Never put any part of your body between the punch and die. Never let your fingers or other body parts come between your workpiece and the machine. Never hold your workpiece over the top of a previous bend. Keep your face and upper body out of the way for workpiece movement. This will keep you from getting slapped (see Figure 5).

- Do not sit in front of a press brake—you may not be able to move out of the way quickly enough in an emergency.

- Never interrupt someone or allow yourself to be interrupted when operating a press brake.

|

| Figure 5: Holding the workpiece over the top of a previous bend is a no-no, as is leaning over a workpiece that is about to be bent, unless you enjoy being slapped in the face by sheet metal. |

Except in an emergency, never try to back a workpiece out of the slip roll while the rollers are still clamped into place. The workpiece is still being rolled regardless of the direction of the roll. This causes the radius to vary for the distance that was traveled by the roller, only in reverse.

Should it become necessary to remove a workpiece from the slip roller before the completion of the work cycle, lift the top roll and remove the piece. Make all the necessary adjustments and then return the workpiece to complete the rolling.

Safety is most important. The following rule always should be obeyed:

NEVER WEAR LOOSE CLOTHING, GLOVES, OR A NECKTIE NEAR A RUNNING SLIP ROLLER. Wearing these garments is the best way to get yourself sucked into the rollers. The slip roller is no more forgiving than a press brake and will relieve you of body parts quickly. Please, be careful!

About the Author

Steve Benson

2952 Doaks Ferry Road N.W.

Salem, OR 97301-4468

503-399-7514

Related Companies

subscribe now

The Fabricator is North America's leading magazine for the metal forming and fabricating industry. The magazine delivers the news, technical articles, and case histories that enable fabricators to do their jobs more efficiently. The Fabricator has served the industry since 1970.

start your free subscription- Stay connected from anywhere

Easily access valuable industry resources now with full access to the digital edition of The Fabricator.

Easily access valuable industry resources now with full access to the digital edition of The Welder.

Easily access valuable industry resources now with full access to the digital edition of The Tube and Pipe Journal.

- Podcasting

- Podcast:

- The Fabricator Podcast

- Published:

- 04/16/2024

- Running Time:

- 63:29

In this episode of The Fabricator Podcast, Caleb Chamberlain, co-founder and CEO of OSH Cut, discusses his company’s...

- Industry Events

16th Annual Safety Conference

- April 30 - May 1, 2024

- Elgin,

Pipe and Tube Conference

- May 21 - 22, 2024

- Omaha, NE

World-Class Roll Forming Workshop

- June 5 - 6, 2024

- Louisville, KY

Advanced Laser Application Workshop

- June 25 - 27, 2024

- Novi, MI